THE RIGHT PEOPLE IN THE RIGHT POSITIONS

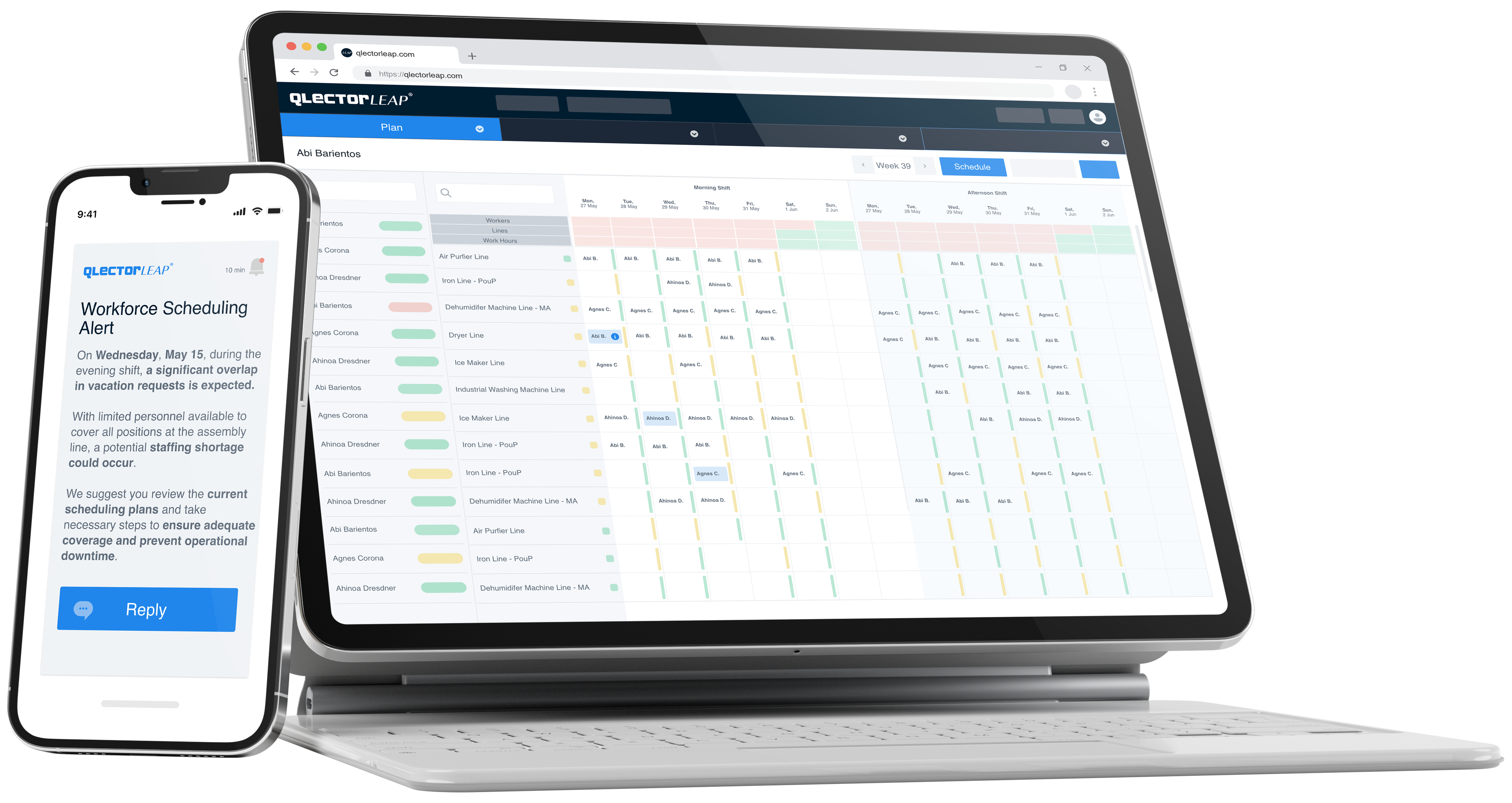

Workforce Scheduling

Optimize workforce schedules with AI that aligns people with production plans, real- time demands, and their availability, skills, certifications, and limitations—ensuring the right person is always in the right place at the right time.

WORKFORCE SOFTWARE FOR MANUFACTURING

Intelligent Scheduling, Real-Time Adaptation

Simplify complex scheduling challenges with just a few clicks. Adapt your plans to demand fluctuations and operational changes in real-time. Utilize the AI-enabled solution that is compliant with GDPR, EU Labor Legislation, and ISO 27001, and can seamlessly connect with your existing ERP and HR systems to enhance productivity, efficiency, and employee satisfaction.

Automatic People & Shift Scheduling

Alerts for Scheduling Conflicts and Unexpected Events

Learning on Workers' Actual Performance & Experience

Task Scheduling & Prioritization

AI-supported

Decision-Making

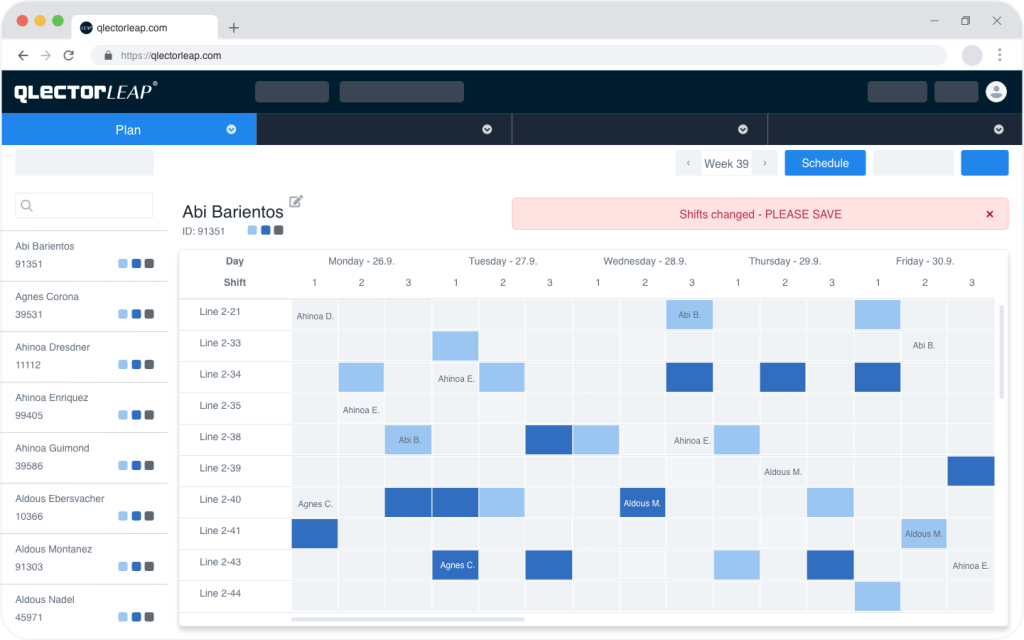

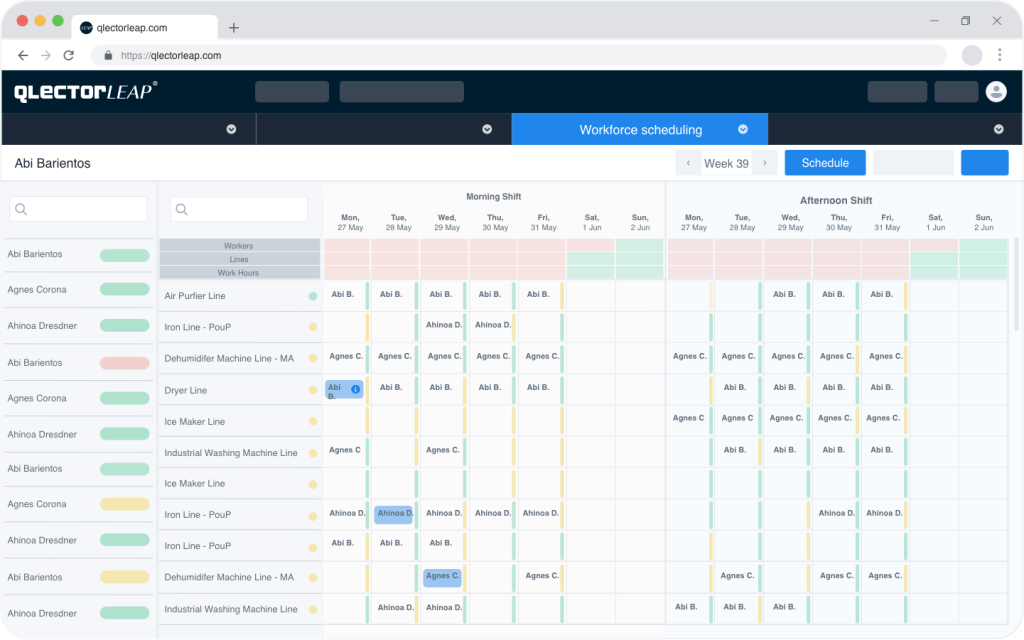

FEATURE HIGHLIGHT #1

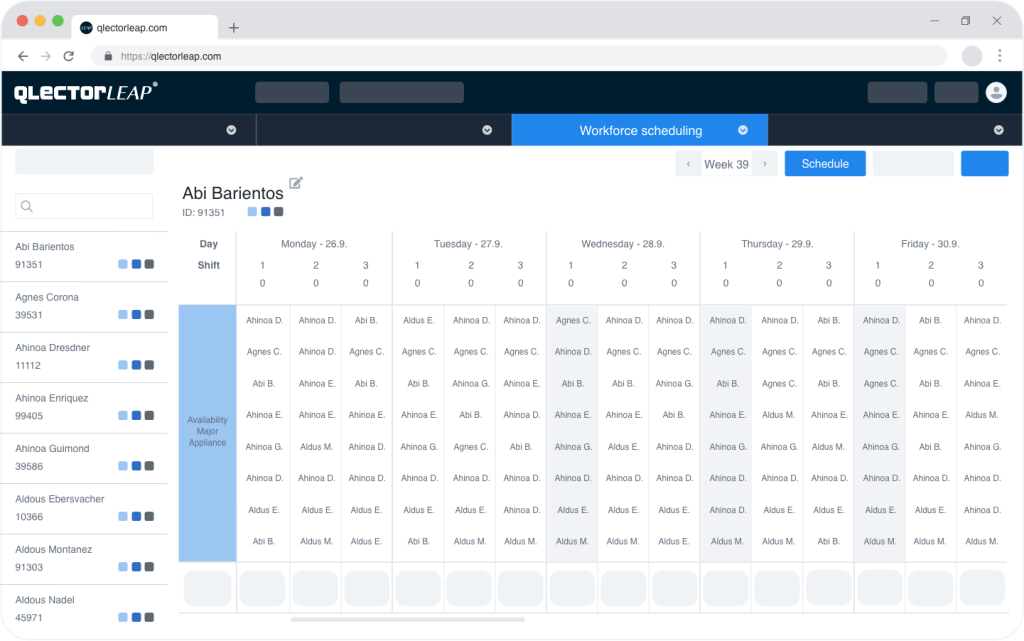

Automatic People and Shift Scheduling

The Automatic People and Shift Scheduling feature seamlessly integrates AI-supported and manual scheduling processes to optimize workforce allocation across various demands and production types. The system offers drag-and-drop functionality, real-time adjustments for unplanned absences, extensive customization of shift plans through templates and advanced filters, conflict alerts, and comprehensive reporting features.

- Fully automated workforce and shift scheduling

- AI-supported plan creation based on various parameters

- Supported plans based on demand (sales, production)

- Application of rotations, different shift plans and models

- Support for different scheduling strategies and production types

- Adjustments in case of unexpected events or unplanned absences

- Various supported scheduling time frame – from hours and shifts up to months

- Matching of required work center/line competencies with workers qualifications and skills

- Manual fine-tuning of AI-created workforce schedules

- Manual creation workforce schedule

- Modern and responsive user interface with Drag & Drop functionality

- Drilldown to scheduling individual workers

- Option to create and use individual templates for easier scheduling

- Enabled mass editing

- User defined advanced filters

- Adding comments and labels for better oversight

- Manual locking of shifts

- Anomaly detection in case of manual scheduling (e.g. missing competences, overlaps, over- and under-staffing)

- Providing alerts for scheduling conflicts and unexpected events

- Real-time reporting

- Required worker demand forecasting

- Export of created schedules

- Enabling managers to focus on strategic KPIs

- Enabling data-driven decision making

FEATURE HIGHLIGHT #2

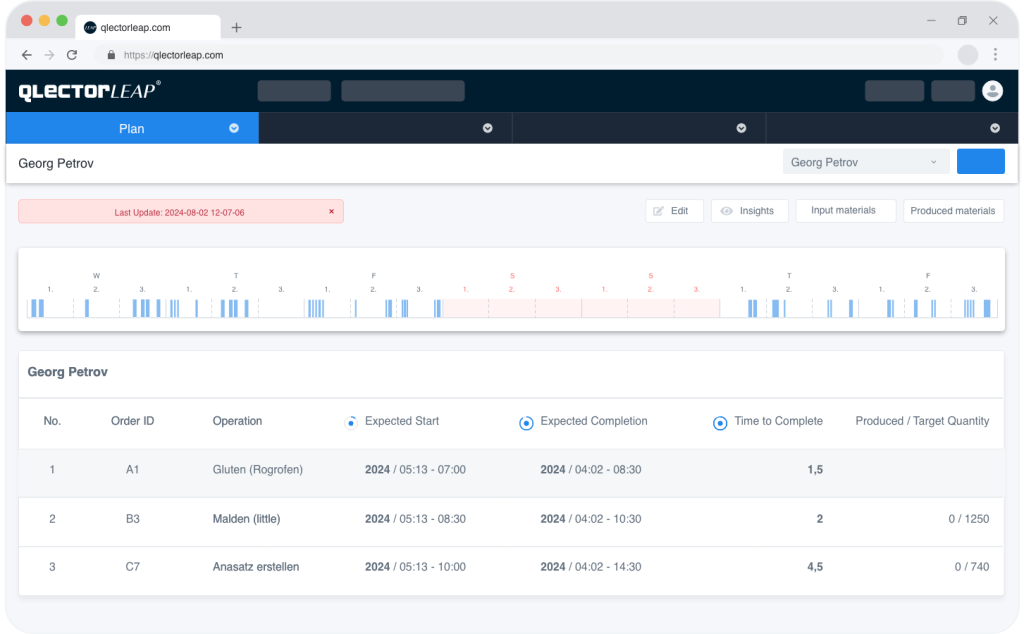

Intelligent Task Scheduling

Benefit from a system that learns and adapts to your operational demands and automatically schedules tasks based on the created plan. It manages and supports mixing tasks for employees across different orders and workplaces. It offers AI-powered task prioritization, based on actual production processes.

- Manage and automatically schedule tasks based on created plan

- Support for mixing tasks on different orders and workplaces

- AI-enabled task prioritization based on actual production processes

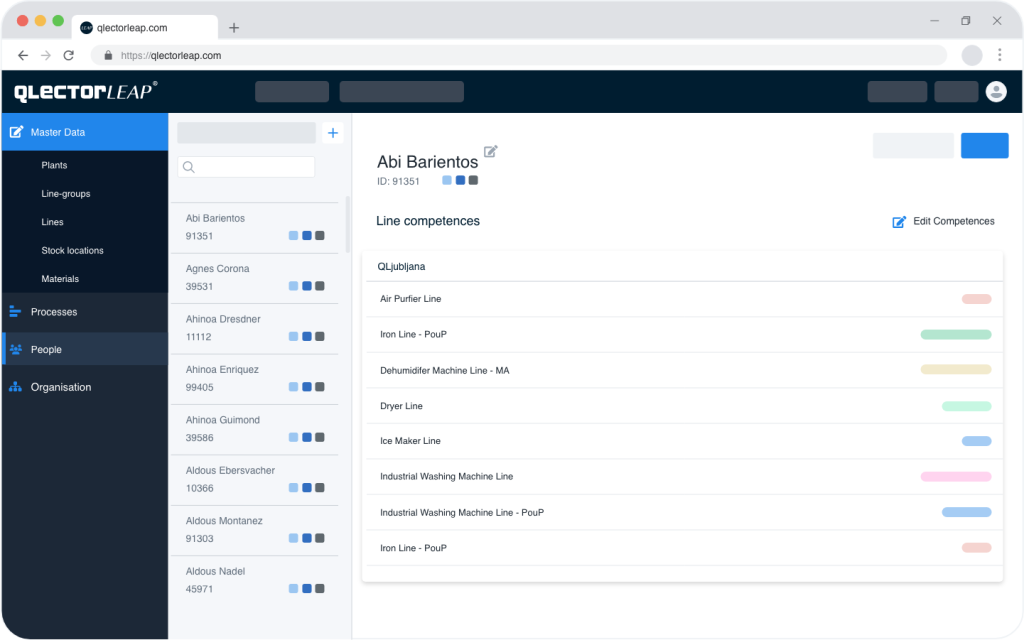

FEATURE HIGHLIGHT #3

Optimal Workforce Allocation

Optimal placement of employees in regard to sales and production demands, aligned with individual worker competencies, skills, licenses, limitations, and availability. The solution automatically creates the best teams based on real-time performance data and regulatory compliance, while facilitating continuous learning and adaptation.

- Most optimal plans and schedules based on:

- Sales or Production demand

- Worker competencies, skills, licenses, and certifications

- Worker limitations

- Regulations (e.g. maximum working hours, breaks, rest periods between shifts, contractual working time)

- Maintenance periods and actual availability of work centers/lines

- Workers actual shop-floor performance

- Worker’s availability (planned and unplanned, location-specific holidays)

- Creation of best performing teams for required demand

- Maximizing production efficiency, worker output, and product quality – digital twins for most optimal plans:

- Learning based on employee performance by generating the best teams - realistic throughput of individuals

- Learning based on experience (frequency of working on specific product, work center/line)

- Schedule either always experienced worker for higher throughput or enable rapid learning/training of less experienced or unqualified workers when scheduled together with experienced mentors:

- Schedule more experienced workers first

- Schedule less experienced workers first

- Schedule without worker history

- Monitoring efficiency and learning during training process

- Optional - Worker’s qualification and limitation data management:

- Data management for workers competencies and limitations

- Ensuring workers' competencies are up to date before scheduling

- Integration of workers qualification and limitation from external IT system

- Transparency of available workers enabling transition of required workers between production departments

FEATURE HIGHLIGHT #4

AI-Supported Decision- Making

Enhance operational efficiency with AI-supported decision-making that reduces scheduling complexity and human errors. It minimizes staffing discrepancies and unplanned overtime, replaces manual scheduling with AI-driven predictions & simulations, and provides alerts for future uncertainties.

- Minimizing the impact of manufacturing complexity and human errors

- Minimize the chance of over- and under-staffing or unplanned overtime

- Eliminate manual preparation of daily workforce schedules, along with Excel spreadsheets, phone calls, or meetings to stay on track

- Providing AI-driven predictions, simulations, insights, and alerts for unexpected events in the future

FEATURE HIGHLIGHT #5

Enhancing Workplace

Create a work environment that values and supports employees. Boost employee satisfaction and compliance through transparent scheduling that enhances workers' experiences. Gain insights into workloads, enrich well-being, and empower staff with tools that benefit both people and the company.

- Manage compliance with scheduling rules while improving employee’s experience.

- Detailed insight into worker's occupancy (workload) based on their quota to maximize employee satisfaction and empowerment.

- Providing scheduling transparency and workload visibility for each worker.

- Enrich employee well-being in ways that benefit both employees and the company.

LEADING THE FUTURE OF WORKFORCE OPTIMIZATION

Start Your WFM Transformation Journey With Us!

With Qlector LEAP’s you can experience the next generation of workforce management (WFM). Enhance your operational efficiency, comply with regulatory requirements, and improve employee satisfaction – all through one intelligent platform!

Demand-Oriented Scheduling:

Fully integrated with your production and ERP systems to reflect real-time demand changes, ensuring optimal workforce allocation.

Seamless Implementation:

Our solution integrates effortlessly with your ERP (production planning, master data) and HR systems or existing WFM system (time & attendance management), guided by a templated and agile rollout process.

GDPR Compliant and ISO 27001 Certified

Adherence to the highest standards of data security and compliance.

Use Cases

DISCRETE MANUFACTURING | AUTOMOTIVE INDUSTRY

-

3 days/week saved for planners

-

25% reduction in downtime with forecasting issues 3 days ahead

-

€300.000/year saved in costs

DISCRETE MANUFACTURING | ELECTRONICS INDUSTRY

-

75 hours/week saved for planners

-

25% less downtime with 10% improvement in JIT production

-

€220.000/year saved in costs

DISCRETE MANUFACTURING | AUTOMOTIVE INDUSTRY

-

10% reduction in lead times

-

€135.000 annual savings from increased efficiency

-

0.5 hours saved per worker through improved task allocation

PROCESS MANUFACTURING | FOOD & BEVERAGE INDUSTRY

-

Extended scheduling horizon by 3 days

-

1-2 days saved in planning

-

5% increase in Overall Equipment Effectiveness (OEE)

PROCESS MANUFACTURING I CHEMICAL INDUSTRY

-

50% Significant Time Savings

-

20% Decrease in organizational downtimes

-

Moving from daily to weekly scheduling

We are SAP Silver Partner

QLECTOR LEAP integration now works seamlessly out ofthe box. SAP, the market leader in enterprise application software solutions, empowers companies of all sizes and across various industries to operate at their best.