INTELLIGENT Production Planning

Make your life on the shop floor easier

Close the gap between production planning theory and shop floor reality. Turn messy spreadsheets into intelligent, optimized plans, powered by your real production data.

Increase Planner Productivity

Increase In-Time Delivery

Reduce Inventory Levels

Control Last Minute Changes

Reduce work-in-progress

INTELLIGENT Production Planning

Make your life on the shop floor easier

Close the gap between production planning theory and shop floor reality. Turn messy spreadsheets into intelligent, optimized plans, powered by your real production data.

The Hidden Costs of Inefficient Production Planning

See how much money potentially leaks from your factory every year, and what you can do to reduce it. Enter a few details, and you’ll quickly receive a tailored estimate of hidden costs directly in your inbox.

The Hidden Costs of Inefficient Production Planning

See how much money potentially leaks from your factory every year, and what you can do to reduce it. Enter a few details, and you’ll quickly receive a tailored estimate of hidden costs directly in your inbox.

OUR CUSTOMERS

Our impact at a glance

40

+

factories

1.300

+

production lines

50

+

implementations

Testimonials

Hear what our clients say

QLECTOR LEAP has enabled significant progress in production plan optimization, as it learns from historical data, intelligently optimizes the plan, and provides optimal suggestions and valuable insights for planners.

Marija Golja

Production Planner at Kolektor

Qlector's software optimizes production planning in a simple, intuitive way and opens up new optimization options in a simple form thanks to the AI algorithms and various evaluations and reports. A must for modern production.

Ingo Hild

Plant Manager at ams OSRAM Group

QLECTOR LEAP has enabled the automation of planners' work, faster response to changes in production planning, and management of a larger number of machines.

Matjaž Roblek

Supply Chain Director at Domel

With QLECTOR LEAP, we've digitally mapped every process. Now, we efficiently formulate production plans, including auxiliary workstations. Plan's automatic updates are a game-changer, keeping all subsidiary processes informed.

Domen Škrbina

Head of Production Logistics at Kovis

INTELLIGENT PRODUCTION PLANNING AND SCHEDULING

Award-Winning Solutions

Built by manufacturing experts and machine learning scientists to help you bridge the gap between planning theory and shop-floor reality.

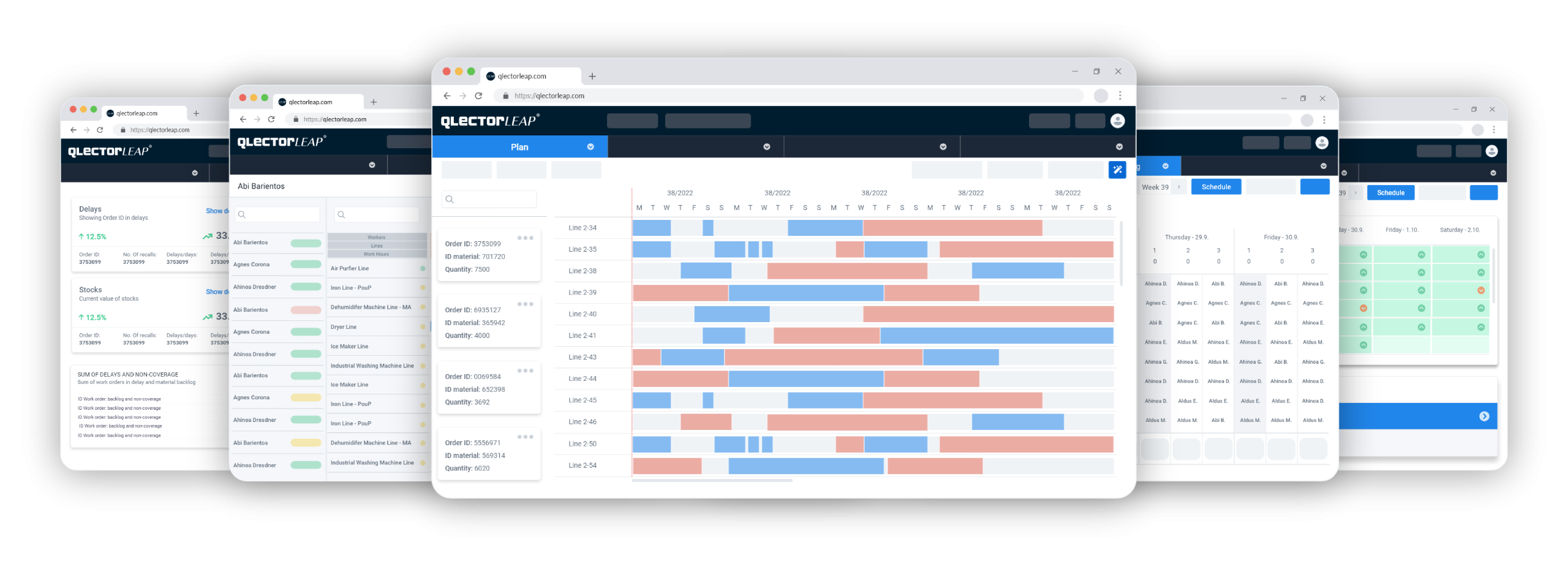

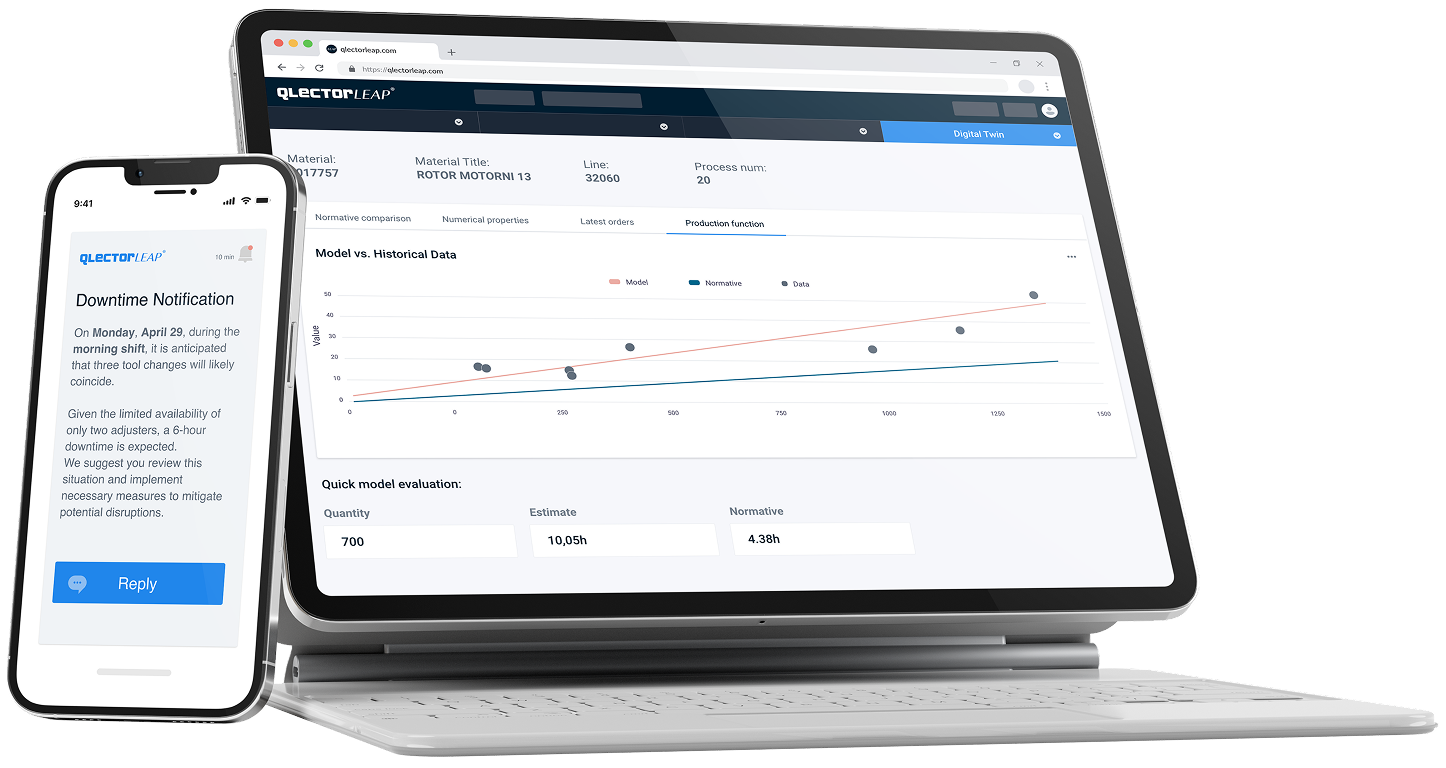

Qlector LEAP Platform

AI-powered solution for realistic production planning, scheduling, and optimization. By creating a digital twin of your production process and material flow, it simulates thousands of scenarios and suggests optimized plans based on your goals, using real data instead of fixed norms.

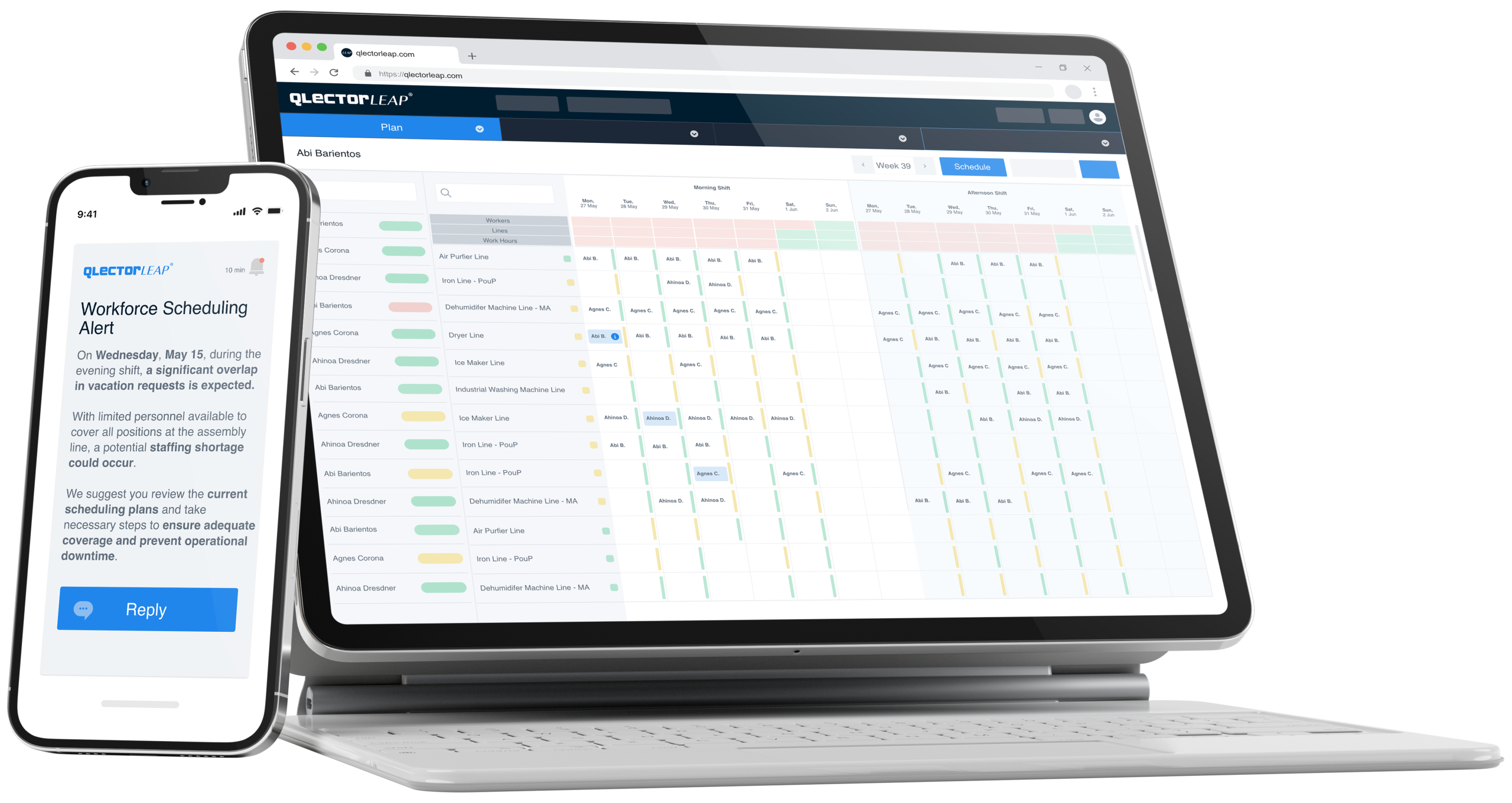

Intelligent Workforce Scheduling

AI-powered workforce scheduling solution that aligns people with production plans, real-time demands, and their availability, skills, certifications, and limitations, ensuring the right person is always in the right place at the right time.

KEY BENEFITS

Less Costs Through Realistic Predictions

Discover the key benefits our customers have achieved across various discrete and process manufacturing industries.

Up to

50%

Increased planner productivity

Up to

15%

Increased on-time delivery (OTD)

Up to

25%

Reduced organizational downtime

Up to

2,5%

Improved OEE

Up to

15%

Time savings for logistic personnel

Up to

20%

Time saved for team coordinators

Up to

10%

Reduced inventory levels and safety stock

Up to

20%

Reduced work-in-progress (WIP)

USE CASES

Real Stories, Superior Productivity

This is how our customers excel in manufacturing with Qlector’s solutions, making everyone’s life on the shop floor easier.

PROCESS MANUFACTURING I CHEMICAL INDUSTRY

Implementing Fast “What-If” Predictive Simulations at Paint Producer’s Plants

Challenges

Inefficient schedules caused frequent issues | Manual scheduling was time-consuming and error-prone | Complex product levels made planning difficult | Knowledge bottlenecks posed continuity risks | Seasonal fluctuations complicated resource and stock…

Benefits

50% Significant Time Savings

20% Decrease in organizational downtimes

Moving from daily to weekly scheduling

DISCRETE MANUFACTURING | ELECTRONICS INDUSTRY

Leap to Advanced Production Planning and a 25% Decrease in Downtimes

Challenges

Managing a wide range of products required extensive planning | Frequent schedule adjustments for recipes, product changes, and cleaning added complexity | Implementing Just-In-Time (JIT) delivery was difficult due to unpredictable demand…

Benefits

75 hours/week saved for planners

25% less downtime with 10% improvement

€220.000/year saved in costs

DISCRETE MANUFACTURING | RAILWAY INDUSTRY

Elimination of 11 Excel Sheets and 10% Optimization of Total Production Time

Challenges

Manual search for available production capacities | Manual planning of production lines in the ERP system | Manual data entry into 11 Excel files | Manual scheduling of individual tasks across work centers | Delays and long delivery timelines

Benefits

100% time saved in the workplace

Optimized production time by 10%

Created more realistic planning scenarios

DISCRETE MANUFACTURING | AUTOMOTIVE INDUSTRY

Saving 3 Days a Week for Team Coordinators and Production Planners

Challenges

Manual planning consumed significant time, leading to inefficiencies and errors | Schedule adjustments required extensive phone and email communication, causing delays | Key knowledge was limited to a few people | Slow response to…

Benefits

3 days/week saved for planners

25% reduction in downtime with forecasting issues 3 days ahead

€300.000/year saved in costs

DISCRETE MANUFACTURING | AUTOMOTIVE INDUSTRY

Reducing Lead Time by 10% for a Multinational Discrete Manufacturer

Challenges

Rising wages increased financial strain | Managing 2000 products and 1500 daily work orders added planning complexity | Long, unpredictable lead times delayed demand fulfillment | Manual labor scheduling was error-prone | Excess inventory…

Benefits

10% reduction in lead times

€135.000 annual savings from increased efficiency

0.5 hours saved per worker through improved task allocation

PROCESS MANUFACTURING | FOOD & BEVERAGE INDUSTRY

Achieving a 5% Increase in OEE for an Austrian Food & Beverage Supplier

Challenges

Last-minute order changes led to inefficiency | Scheduling was hindered by bottlenecks | Failed attempt to digitize scheduler knowledge increased company risk, highlighting the need for a more robust solution

Benefits

Extended scheduling horizon by 3 days

1-2 days saved in planning

5% increase in Overall Equipment Effectiveness (OEE)

Ready to solve your planning challenges?

Talk to an expert and explore the potential of Qlector LEAP on your shop floor.