Digital Twin Platform

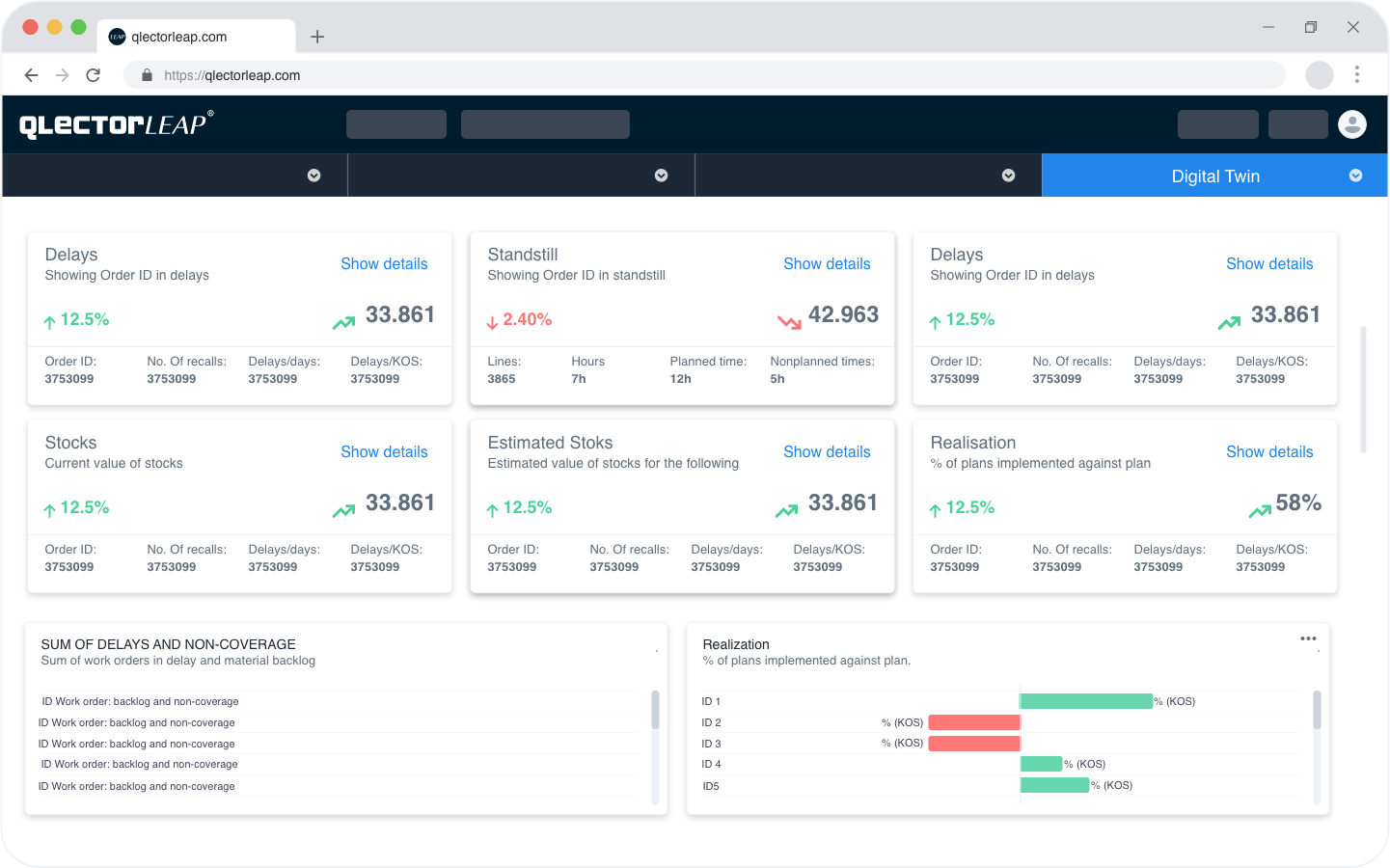

The main benefit for users of Qlector Leap when implementing our digital twin technology is the ability to optimize and streamline operations in real time, leading to increased efficiency, reduced downtime, and improved decision-making based on accurate, data-driven insights.

DIGITAL TWIN OF ALL LINES & SITES

Data Driven Replicas of All Production Lines and Sites

Digital twins as virtual replicas of physical production processes are the foundation of smart manufacturing. They enable users to simulate, analyze, monitor, guide, and optimize systems in real time. Along with artificial intelligence and machine learning, they accelerate and improve the performance of physical assets by analyzing complex data sets and dynamically adapting decision making in manufacturing.

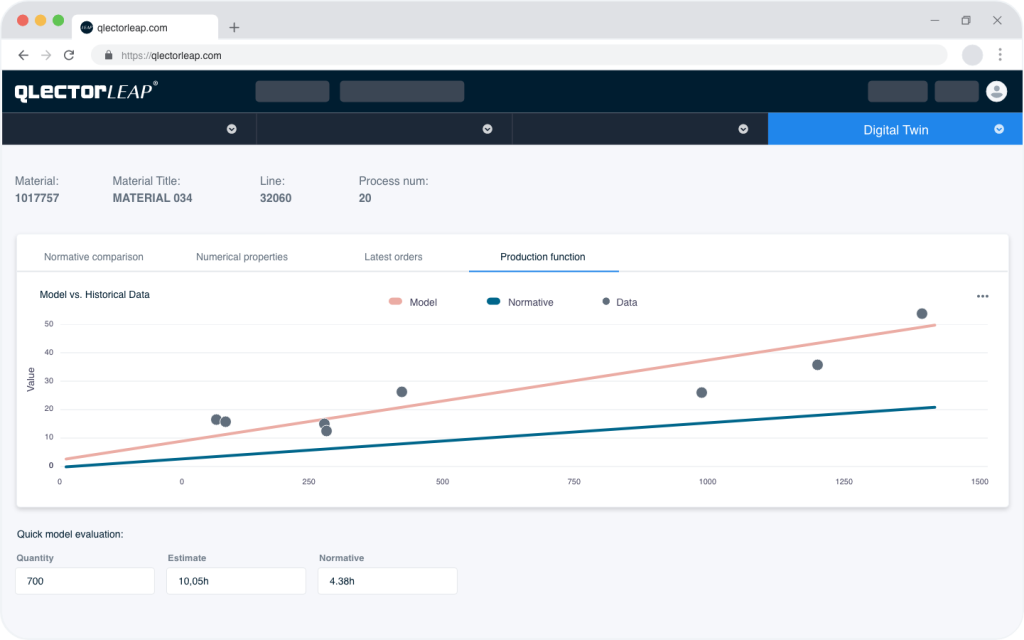

Learning of Realistic Production Times

Based on historical data, we learn the actual production times and routings and suggest more realistic future production times than those set by fixed (static) norms. This enables the comparison of master data norms with actual production metrics, keeping the company’s master data up to date.

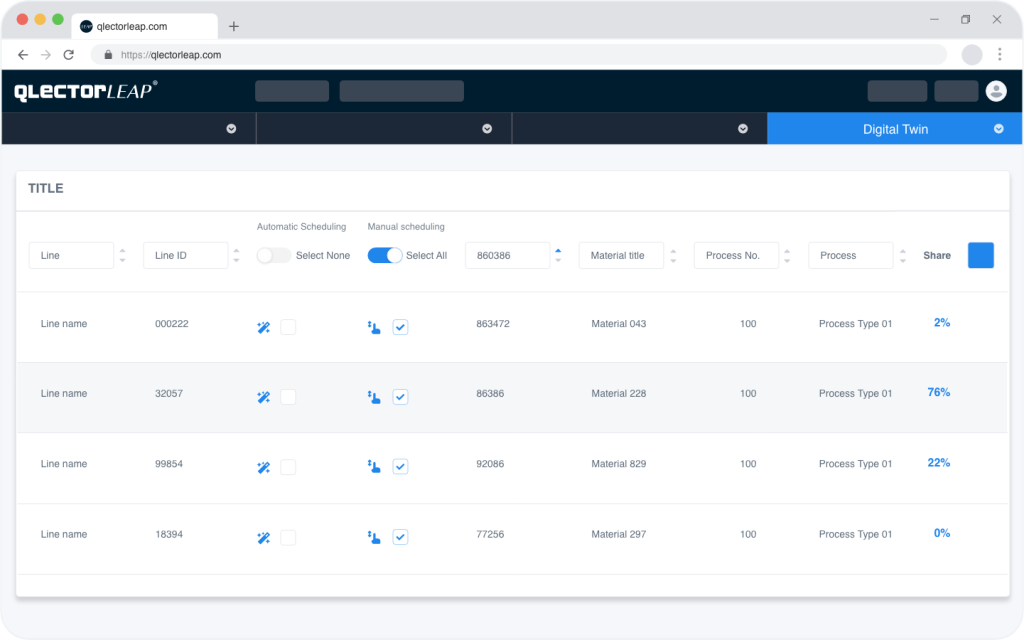

Simulations and Updates of Production Plans

Our Qlector Leap solution uses hundreds of predictive models to perform simulations and update production plans. We capture data from the shop floor and continuously update, learn and adjust the data on realistic production times accordingly.

Optimization by Key User Criteria

Using advanced AI optimization methods, we prepare the most optimal production plans based on key user criteria such as intermediate inventories, tool setup times, and customer prioritization, ensuring streamlined operations and high productivity.

DIGITAL TWIN CREATION

Building Models and Knowledge Graphs

We create a data-driven digital twin of all production lines and sites by learning and building models and knowledge graphs from data that comes from MES and ERP systems. We empower production and supply chain planners and team coordinators to create optimal plans and maintain lean production, closing the gap between production planning theory and shop floor reality.

CALCULATING TIME

Predicting Production Times

We use AI and the digital twin of the factory to predict how much time it will take to produce all products, to identify potential problems, and to suggest alternative routings if unplanned events occur (such as standstills).

DATA INTEGRATION

Merging ERP with MES & Keeping Master Data Up-to-Date

By merging ERP data with production data from MES and other related systems (APS, SCM solutions), we enable users to compare standard guidelines (norms) from master data with actual production metrics. This comparison aids in identifying anomalies and continually improving the accuracy of the company’s master data.

Use Cases

DISCRETE MANUFACTURING | AUTOMOTIVE INDUSTRY

-

3 days/week saved for planners

-

25% reduction in downtime with forecasting issues 3 days ahead

-

€300.000/year saved in costs

DISCRETE MANUFACTURING | ELECTRONICS INDUSTRY

-

75 hours/week saved for planners

-

25% less downtime with 10% improvement in JIT production

-

€220.000/year saved in costs

DISCRETE MANUFACTURING | AUTOMOTIVE INDUSTRY

-

10% reduction in lead times

-

€135.000 annual savings from increased efficiency

-

0.5 hours saved per worker through improved task allocation

PROCESS MANUFACTURING | FOOD & BEVERAGE INDUSTRY

-

Extended scheduling horizon by 3 days

-

1-2 days saved in planning

-

5% increase in Overall Equipment Effectiveness (OEE)

PROCESS MANUFACTURING I CHEMICAL INDUSTRY

-

50% Significant Time Savings

-

20% Decrease in organizational downtimes

-

Moving from daily to weekly scheduling

We are SAP Silver Partner

QLECTOR LEAP integration now works seamlessly out of the box. SAP, the market leader in enterprise application software solutions, empowers companies of all sizes and across various industries to operate at their best.