A realistic production plan is built on quality data and experience. Production plans must be maintained due to the constant change on the shop floor. Collecting feedback from shop floor can be carried out by phone, emails, and most effectively, by meetings. But what happens if suddenly the planners are moved to central offices and collecting feedback becomes difficult or impossible?

Production planning is a complex job

Production planning is a very complex job. It requires a special skill set, such as multitasking, good communication, and time management. It takes years of practice to build realistic plans. Predominantly to understand the specificity of the production and to build strong relationships with colleagues from shop floor.

Shop floor reality

If a planner focuses on planning weeks, months, team coordinators focus on hours and days. It is not possible for a planner to take into account all uncertainties in a production process when building a plan. It is up to team coordinators to schedule production orders and to react to downtime, changes related to human resources, materials, and quality.

Information transfer between a planner and a team coordinator

A solid relationship between planner and team coordinator is essential for a smooth production process. Information transfer includes adjusting a production plan for shoop-floor for scheduling and constant communication with team coordinators on a current status.

If unplanned downtime, resource, or material shortage happens, the team coordinator is responsible to find a quick solution. If the problem is too big, a team coordinator asks the planner to find a new solution or in the worst-case scenario notifies the sales team to inform a customer about the possible delay.

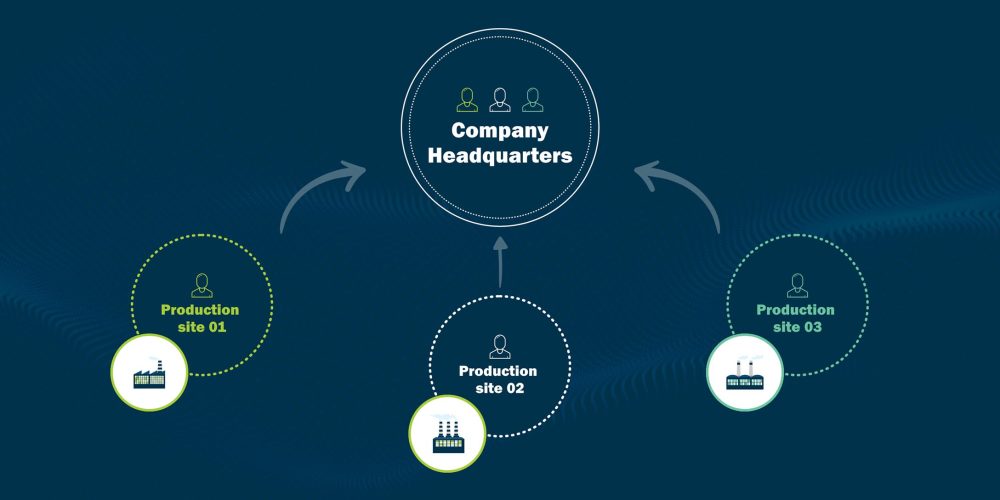

Moving from shop floor to headquarters

Even though production processes run smoothly, there is always a necessity to improve the processes further. Especially, in the multi-production-site companies, there is a necessity to seamlessly connect the production.

To improve communication between the sites and reduce expenses companies tend to move their planners to one location. However, that collapses the existing balance, and setting a new one might be a painful process.

Problems pop-out

Moving planners to headquarters opens new issues and amplifies existing problems. If a poor data quality of production realization was compensated by regular walks through shoop-floor and morning meetings with the production team, a new way of communication must be established.

To overcome this problem planners rely on the communication over the phone, spending a considerable part of the day checking current state of the production and levels of intermediate inventory.

Closing gap with technology

New technologies, such as artificial intelligence, can improve information transfer from the shop floor to a planner and vice versa. Artificial intelligence is used to build a digital twin based on historical data.

A digital twin is utilized to forecast production based on actual capabilities, considering realistic production time and scrap, human resources, and suppliers. In addition, artificial intelligence helps to automate repetitive tasks such as checking realization and inventory levels.

What are the lessons to be learned from this?

By moving planners from shop floor to headquarters opens a new set of challenges. Utilizing new technologies can help with a transparency of production processes, improved information transfer, and automatization of repetitive tasks.

An experienced digitalization partner with extensive knowledge in artificial intelligence can help you not only to overcome the transition issues but also transition a company with higher added value and more satisfied employees.