- Proven Technology, Trusted for a Decade

Since 2015, industry leaders have relied on our in-house Machine Learning technology for secure, reliable, and real-world results.

- Works with Any MES or ERP

No need to change your existing systems—QLECTOR LEAP integrates smoothly with any ERP or MES for seamless advanced planning.

- Three Main Modules

QLECTOR LEAP consists of three main modules, which are layered on top of our AI platform, serving as a foundation for implementing advanced production planning and scheduling features.

Features

Harness the power of our advanced features

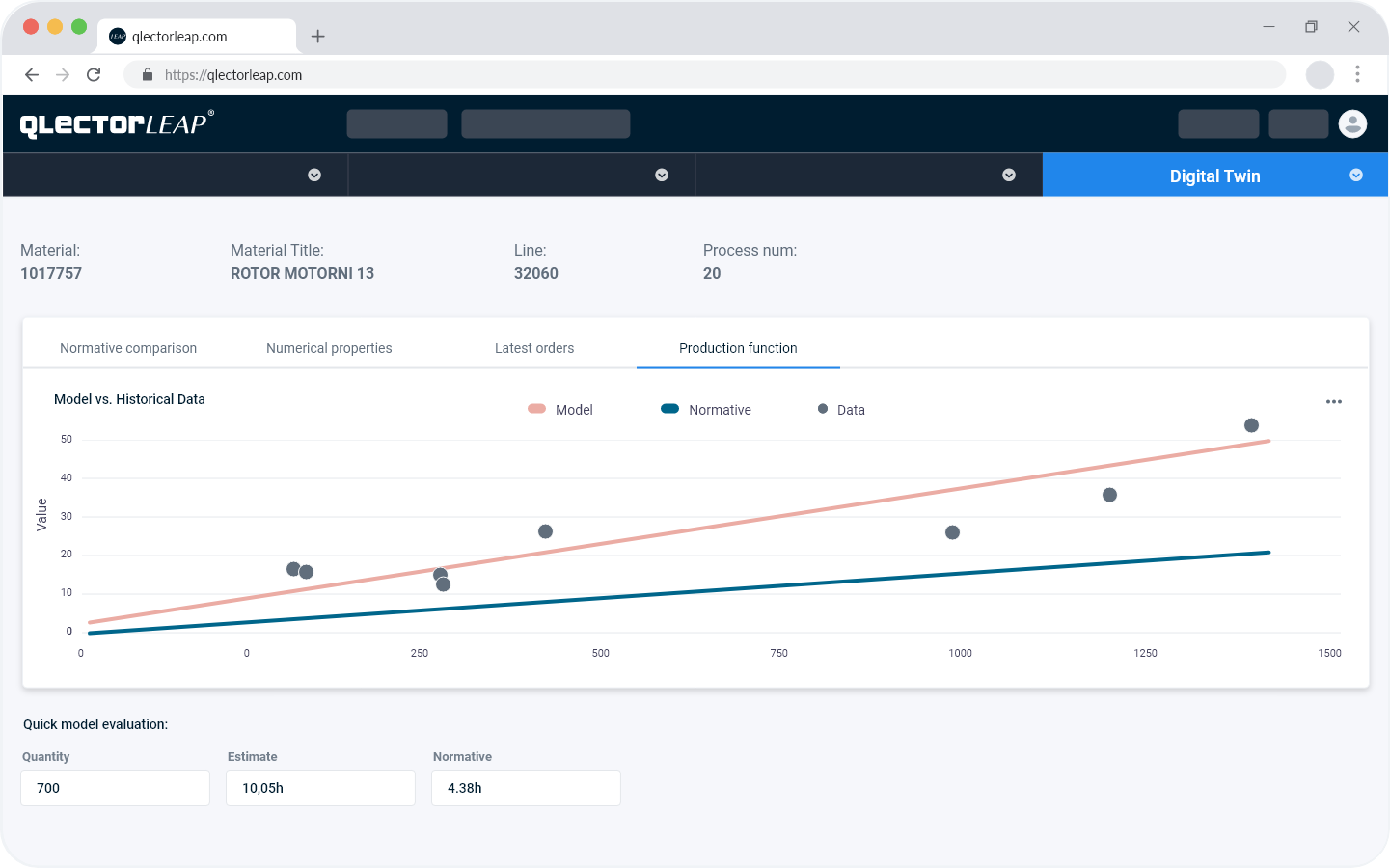

Digital Twin Module

Digital Twin Platform

Building and maintaining a scalable, data driven digital twin of the factory using a knowledge graph of the entire production process. Our cognitive digital twin can understand, self-learn, and adapt to new real-world data.

Master Data Management AI Assistant

Comparing datasets between theoretical norms (ERP) and real-time shop floor data (MES), identifying anomalies and discrepancies to improve the accuracy of master data. This ensures more realistic production schedules, leading to increased output.

Data Anomaly detection

Identifying and addressing deviations from standard manufacturing processes with robust anomaly detection in real-world manufacturing capabilities and execution.

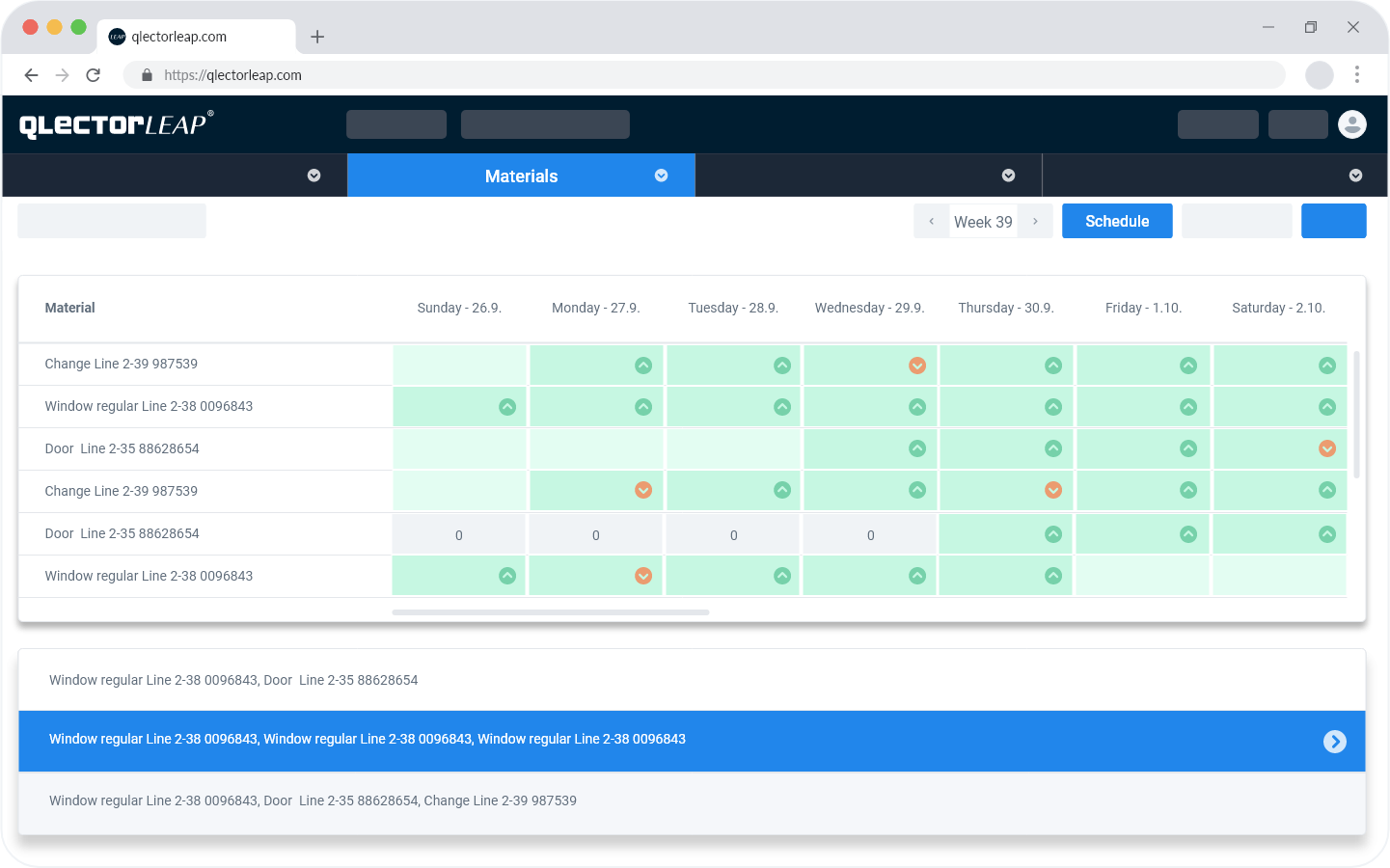

Product Guiding Module

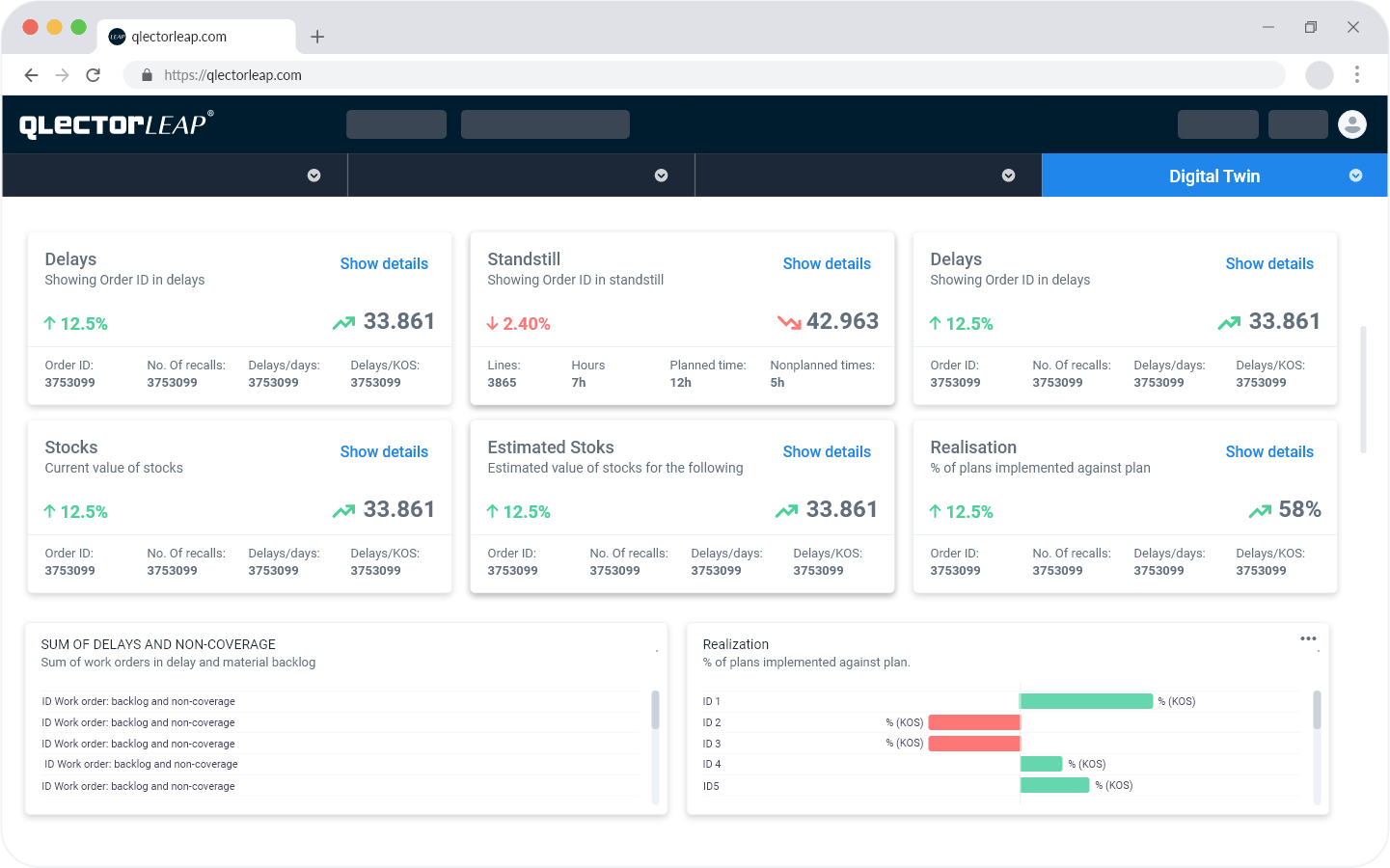

Unified Dashboard for Production Guiding

AI-based predictive production guiding platform with unified dashboard connects different departments providing them with transparency and actionable insights. This intuitive tool facilitate communication, planning processes, material flow tacking, workforce scheduling etc.

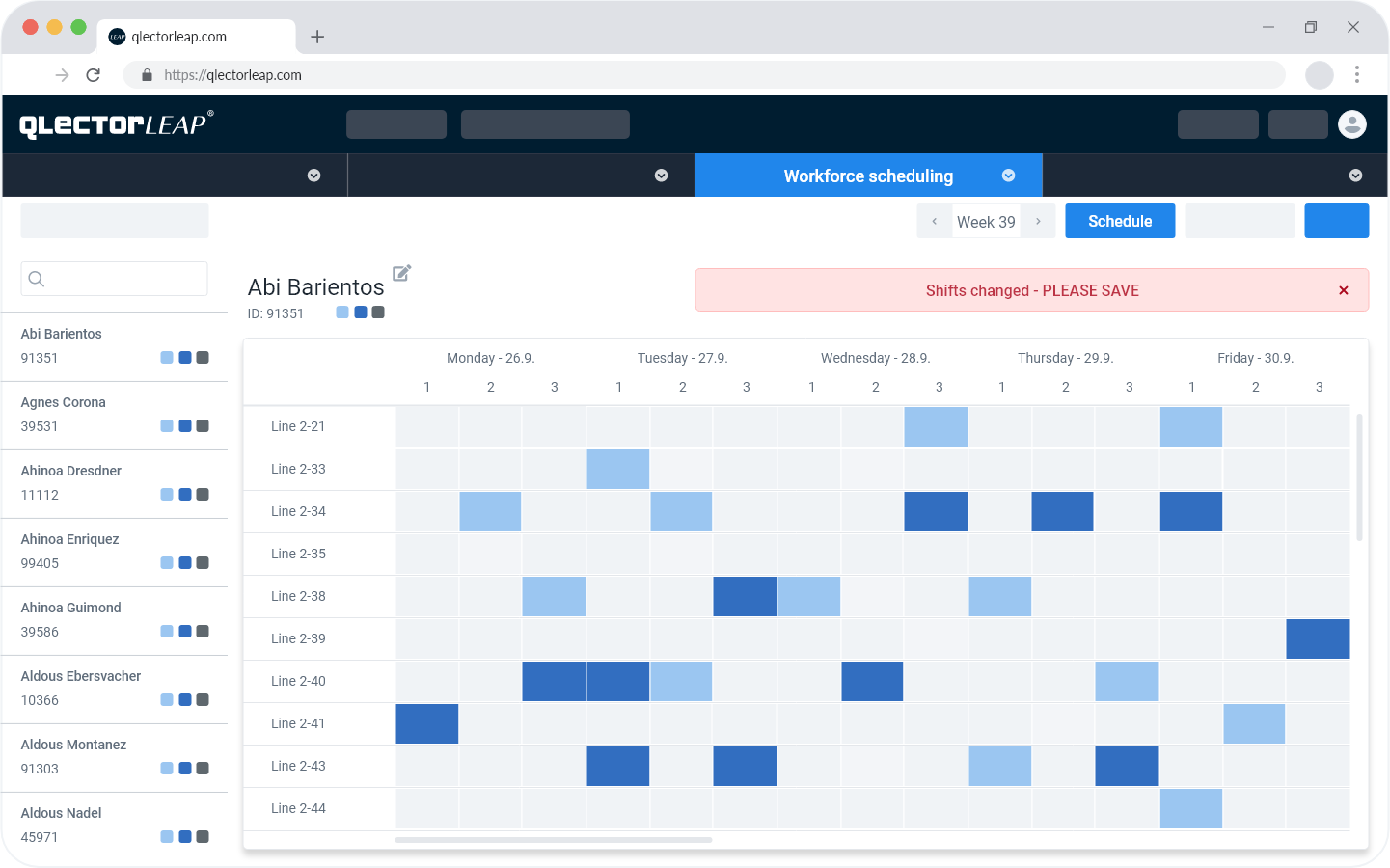

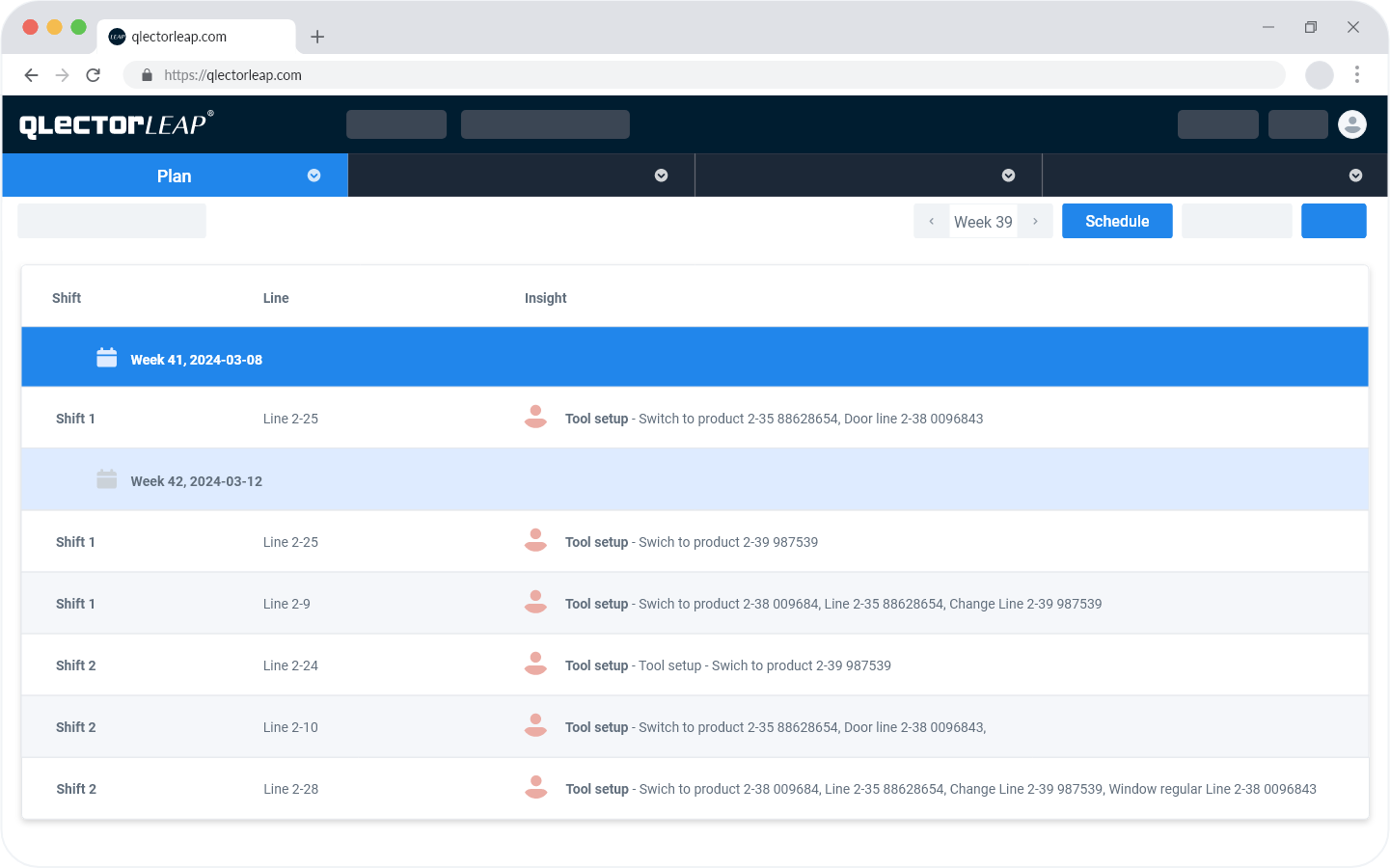

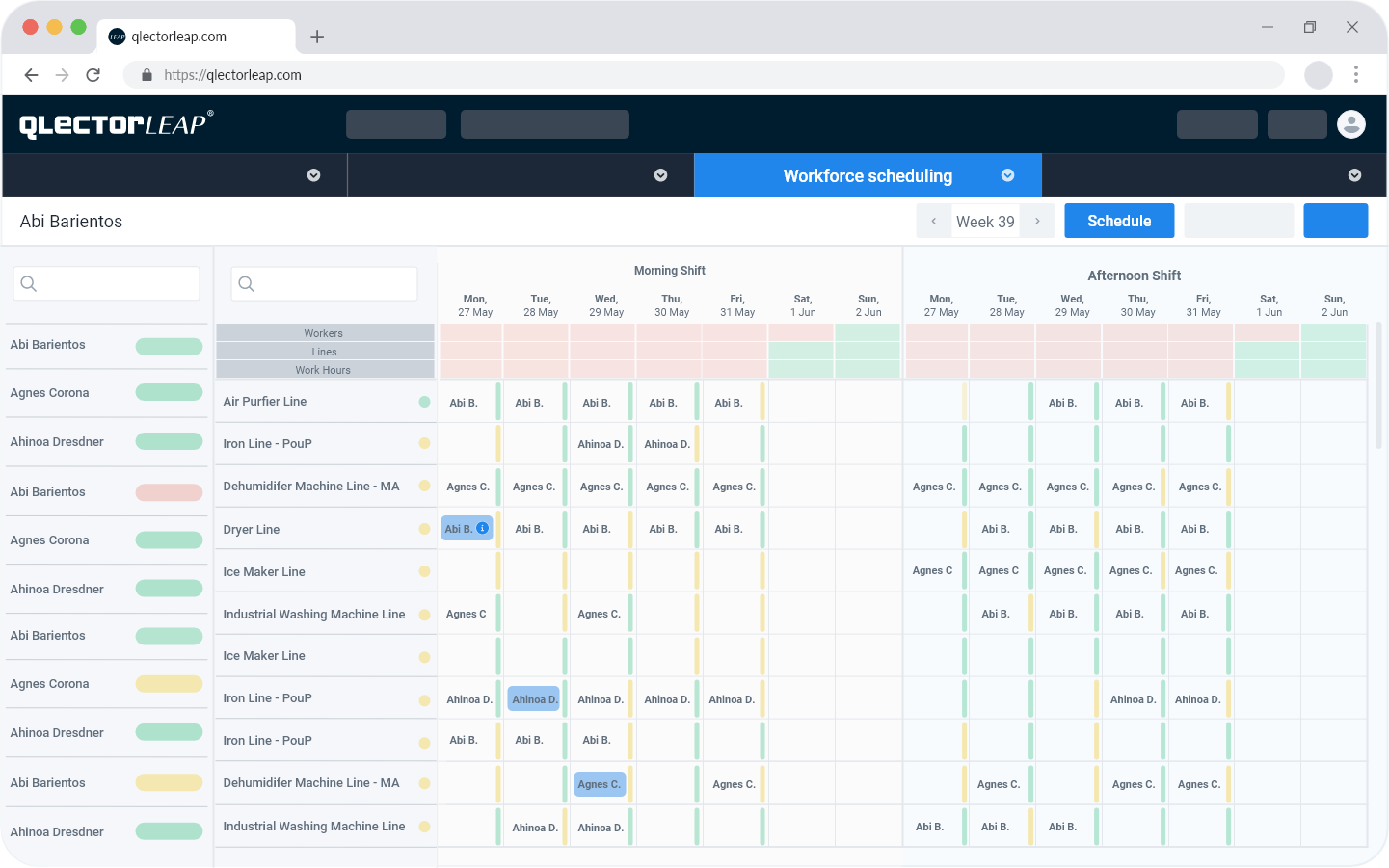

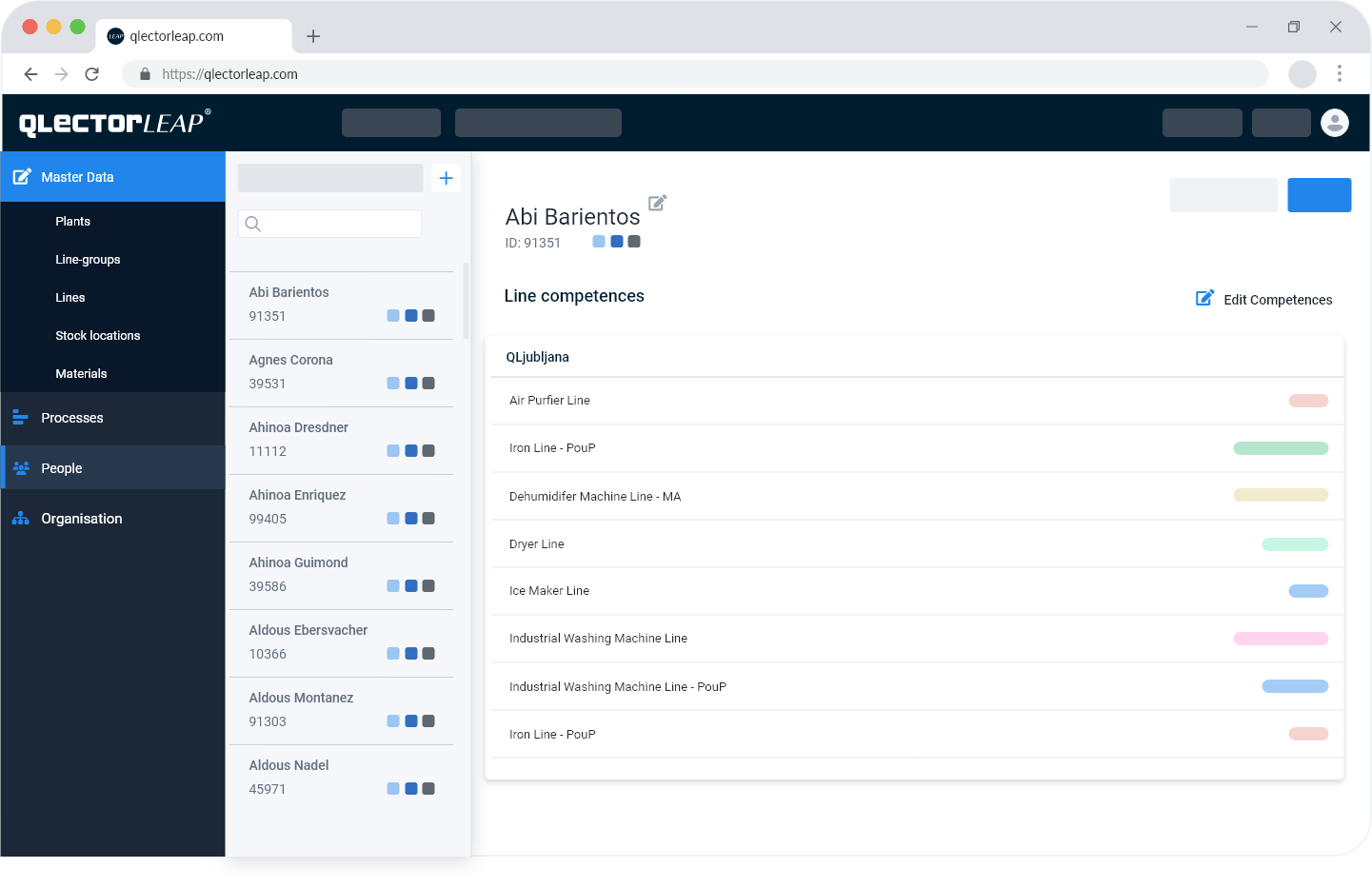

Workforce scheduling

Building a data-driven digital twin of each worker based on their competences, limitations (including regulations), actual shop-floor performance, and availability. This ensures manufacturing companies to place the right people in the right positions, allowing the creation of optimized work schedules to maximize production efficiency.

Anomaly detection

Detecting anomalies in production line setups, realization, stock, and providing prediction-based insights.

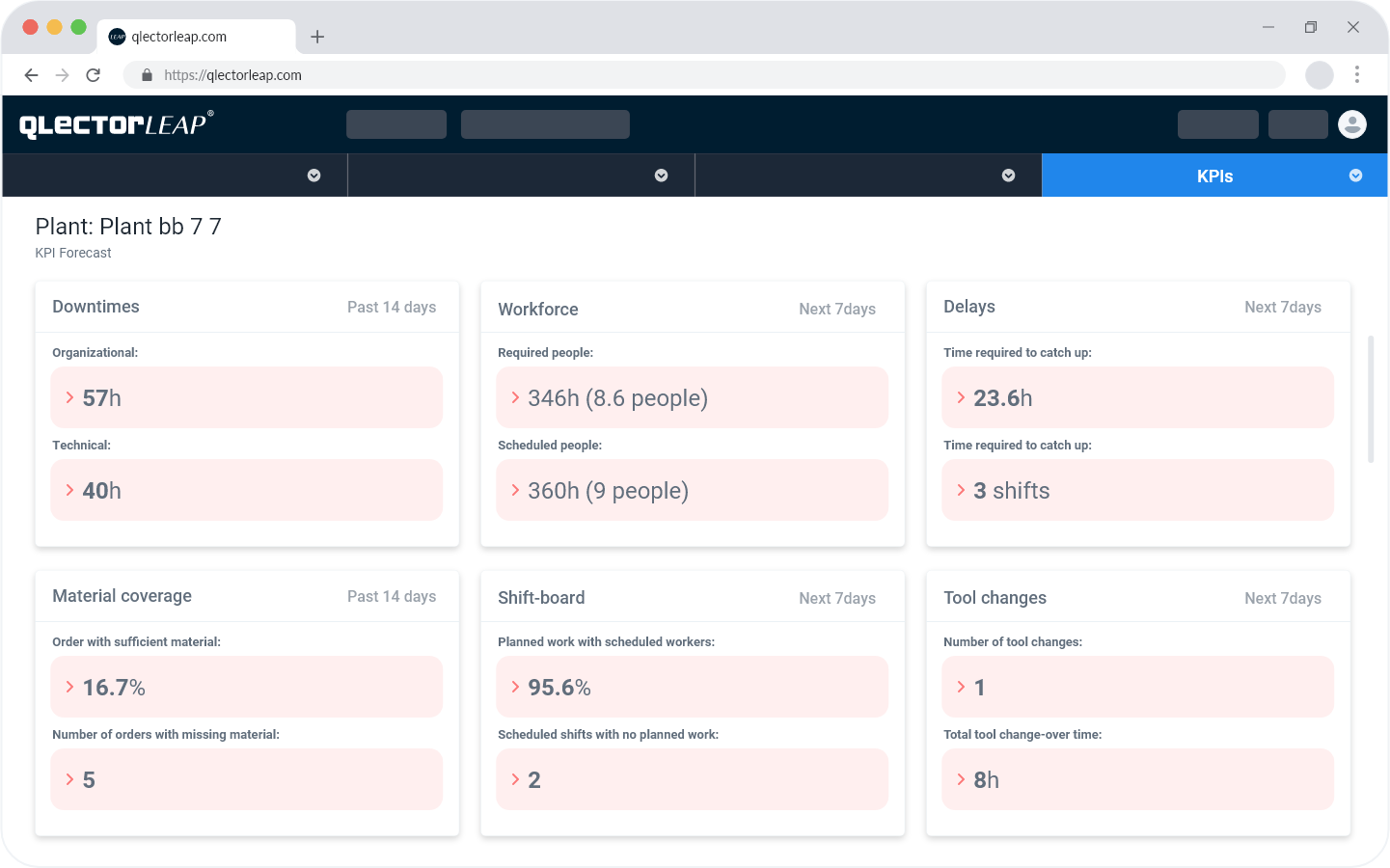

KPIs Calculation & Forecast

Calculating and comparing KPIs for different planning scenarios, including future forecasts.

Decision making

Automated sequencing integrates production and supply chain optimization to generate realistic scenarios for the entire plant’s production processes. This functionality is based on advanced AI models that continuously evolve with the arrival of new data.

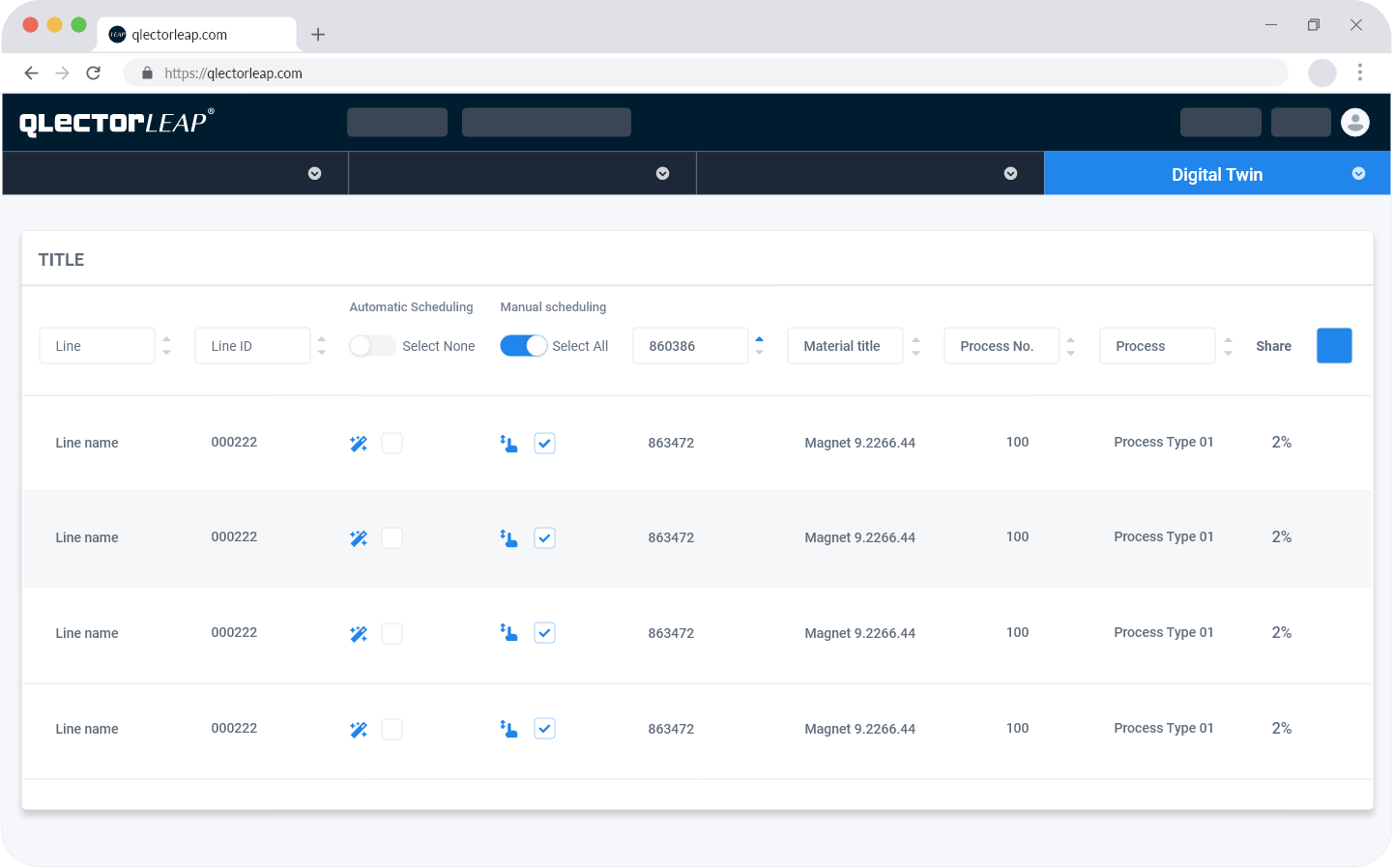

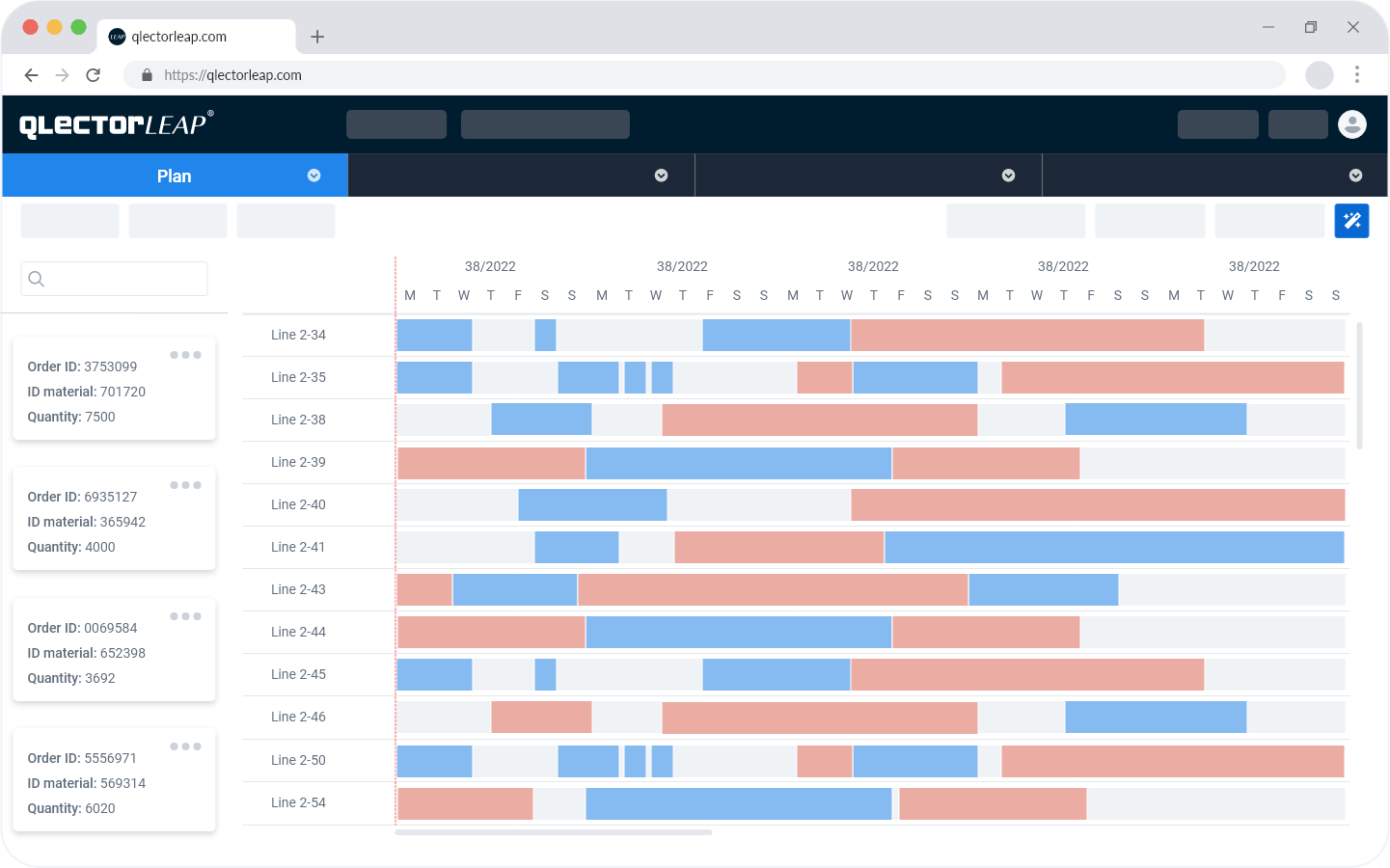

Production Optimization Module

Automatic Optimization

Automated sequencing integrates production and supply chain optimization to generate realistic scenarios

Adaptability

Providing predictions, simulations, insights, and alerts for unexpected events, enabling intelligent decision-making with minimal human intervention and proactive actions taken before unplanned events occur.

TRANSFORMING MANUFACTURING

Transparency and Optimization Across All Production and Supply Chain Processes

Create a data-driven cognitive digital twin of your entire factory. Enable efficient master data management (MDM) and data anomaly detection. Schedule and plan your production processes with prediction-based insights and optimize decision making with minimal human intervention.

Data-driven cognitive

digital twin

QLECTOR LEAP is an AI platform with a data-driven cognitive digital twin, providing transparency and optimization across all production and supply chain processes. Our cognitive digital twin is developed to understand, self-learn and adapt to new real-world data.

Master data

management

Utilizing real-time data and self-learning capabilities, it empowers manufacturers to maximize asset and resource utilization while effectively managing and maintaining master data.

Optimized plans

and schedules

The platform leverages historical data to optimize production plans and schedules, simultaneously enabling shop floor anomaly detection to boost efficiency and productivity.

Intelligent

decision-making

With predictions, insights, and real-time alerts for unexpected events, it enables intelligent decision-making with minimal human intervention.

Workforce

Scheduling

By building a data-driven digital twin of each worker, incorporating their competences, limitations, performance, and availability, companies can now place the right people in the right positions. This allows the creation of optimized work teams and schedules, maximizing efficiency.

KPIs Calculation

and Forecast

Calculating and comparing KPIs for different planning scenarios, including future forecasts, enables organizations to make data-driven decisions that optimize production efficiency and resource allocation.

Start Optimizing

Your Production Now!

We are SAP Silver Partner

QLECTOR LEAP integration now works seamlessly out ofthe box. SAP, the market leader in enterprise application software solutions, empowers companies of all sizes and across various industries to operate at their best.