Our Customers

Why Manufacturers

Trust Us

Discover how plant managers, supply chain managers, and production planners achieve peace of mind with Qlector's solutions.

"QLECTOR LEAP has enabled significant progress in production plan optimization, as it learns from historical data, optimizes the plan, and provides more optimal suggestions for planners and production."

"Qlector's software optimizes production planning in a simple, intuitive way and opens up new optimization options in a simple form thanks to the AI algorithms and various evaluations and reports."

"QLECTOR LEAP has enabled the automation of planners' work, faster response to changes in production planning, and management of a larger number of machines."

Our impact at a glance

Award-Winning Solutions

Built by manufacturing experts and machine learning scientists to help you bridge the gap between planning theory and shop-floor reality.

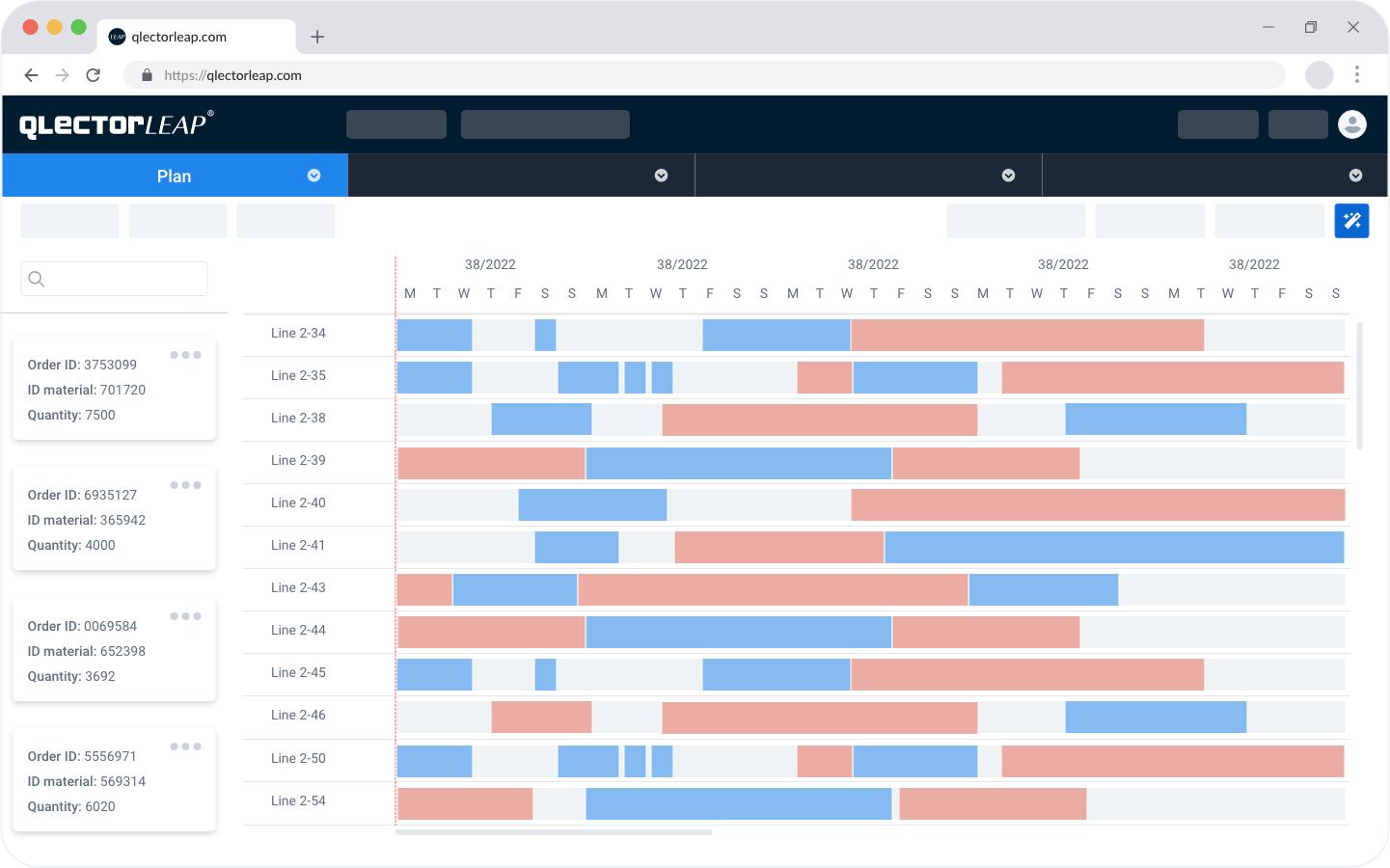

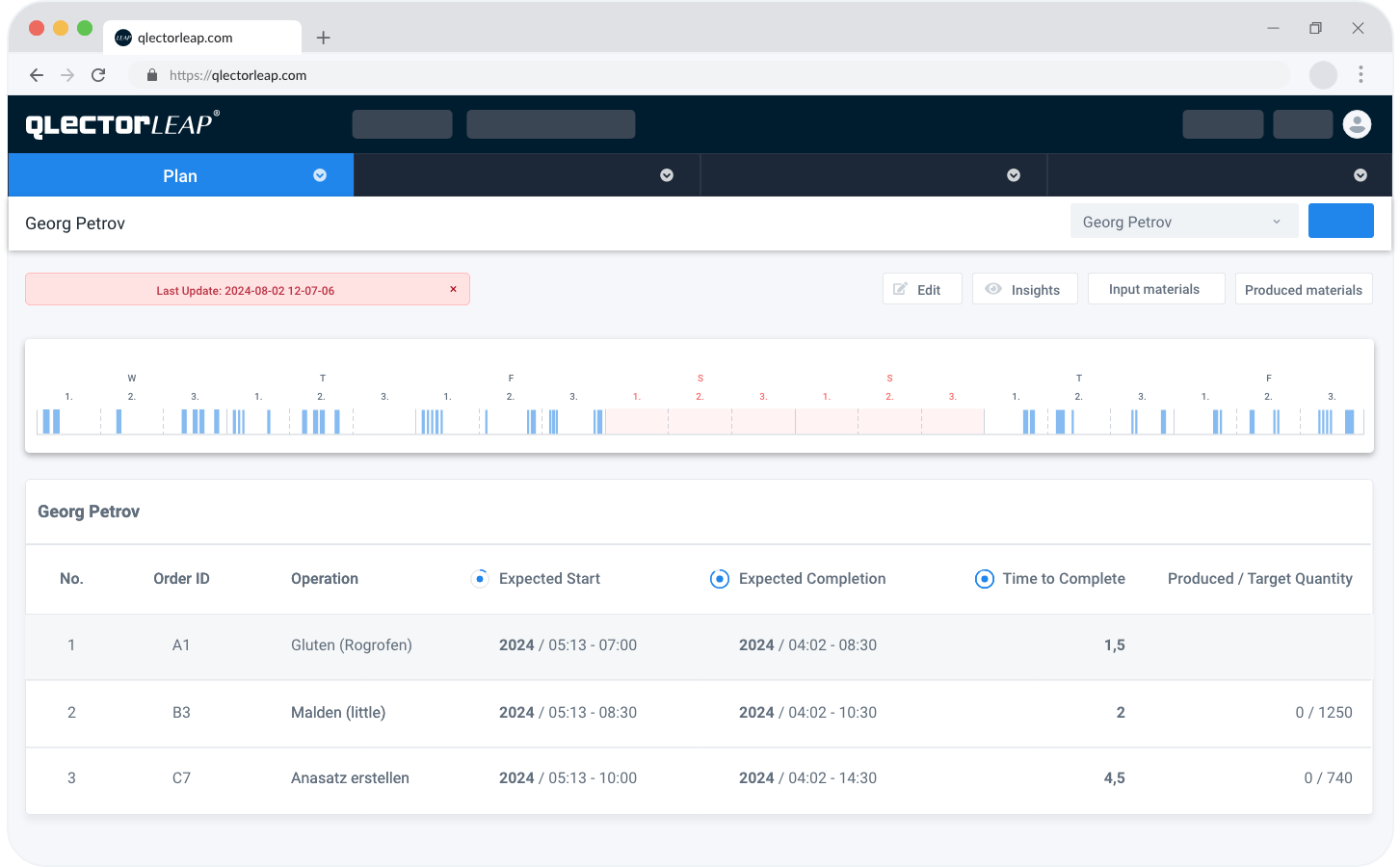

Intelligent Production Planning

Qlector LEAP is an AI-powered solution for realistic production planning, scheduling, and optimization. By creating a digital twin of your factory, LEAP generates smarter schedules based on thousands of improvements and suggests optimized plans aligned with your goals, using only your data instead of best-name theories.

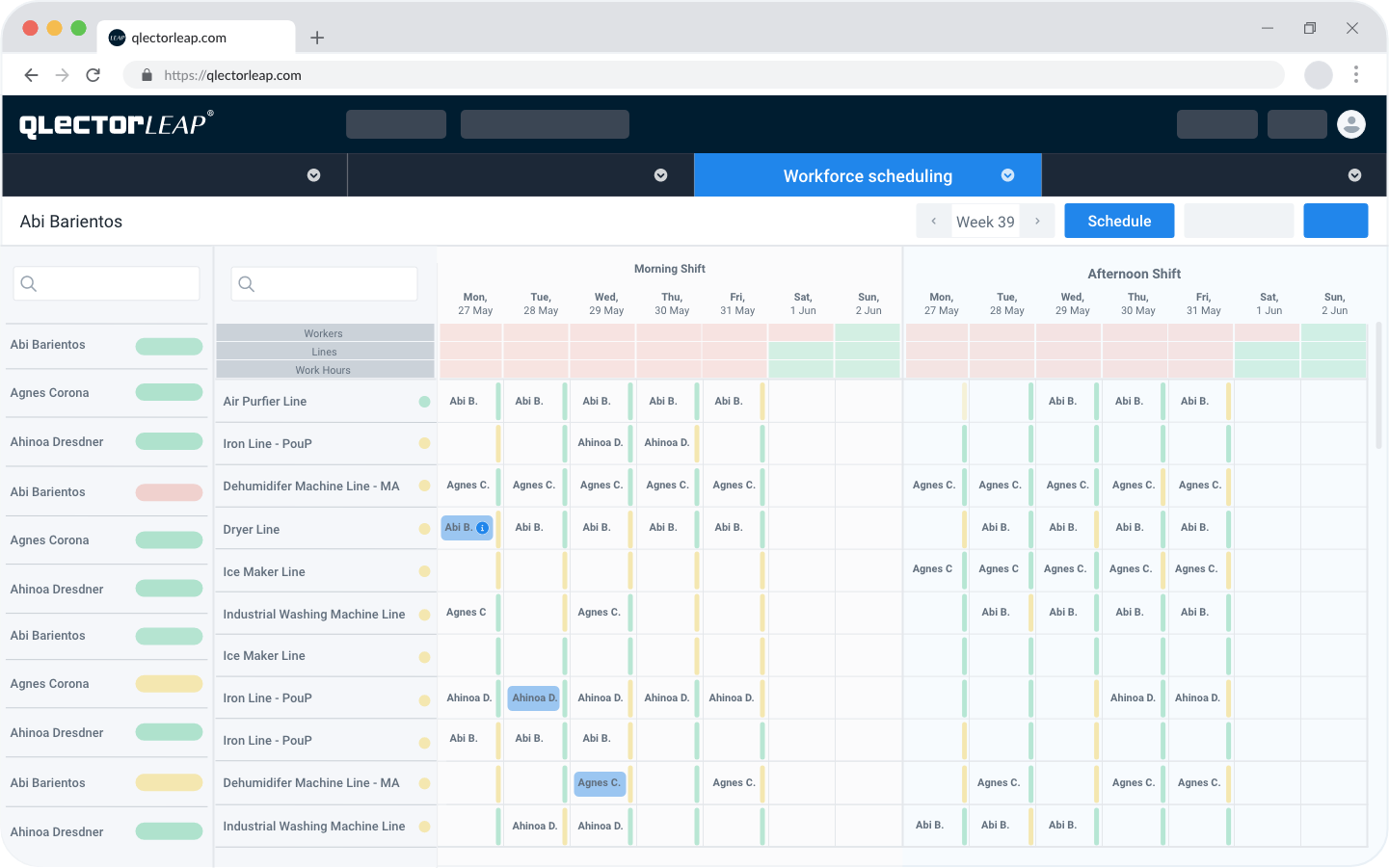

Intelligent Workforce Scheduling

An AI-powered workforce scheduling solution that is reliable, secure, and fully integrated with existing IT, ERP, and HR systems. It aligns people with production plans based on real-time availability, skills, certifications, and regulations, ensuring the right person is always in the right place at the right time.

Efficiency Through Realistic Predictions

Discover the key benefits our customers have achieved on average across various discrete and process manufacturing industries.

Intelligent Production Planning Solution

Learn why leading global manufacturers trust Qlector LEAP - an intelligent

production planning solution.

See how it works and what technology powers it.

Proven Technology, Trusted for a Decade

Since 2015, industry leaders have relied on our in-house Machine Learning technology for secure, reliable, and real-world results.

Works with Any MES or ERP

No need to change your existing systems—QLECTOR LEAP integrates smoothly with any ERP or MES for seamless advanced planning.

Three Main Modules

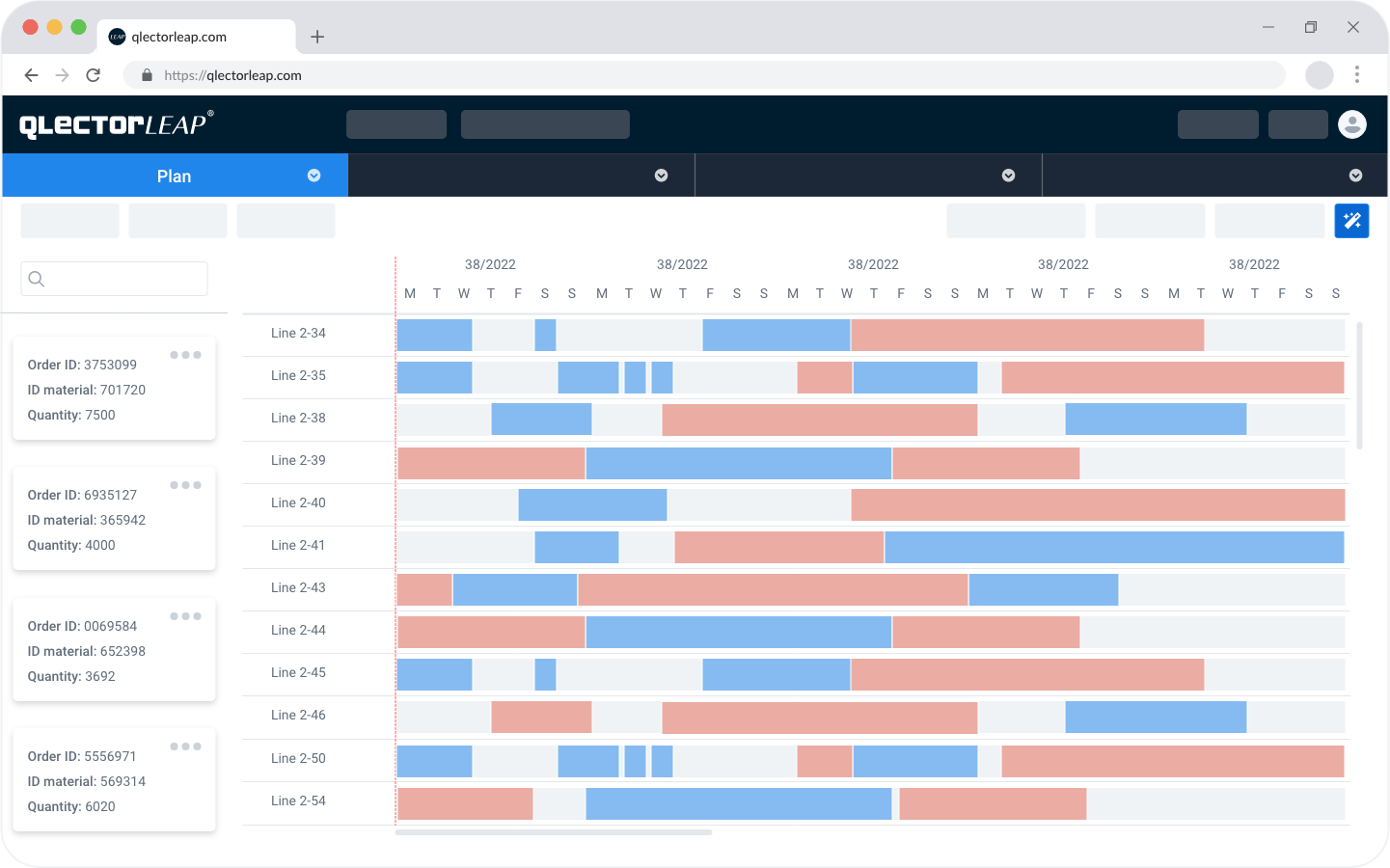

Qlector LEAP consists of three main modules, serving as a foundation for implementing advanced production planning and scheduling features.

Planning That Reflects Reality

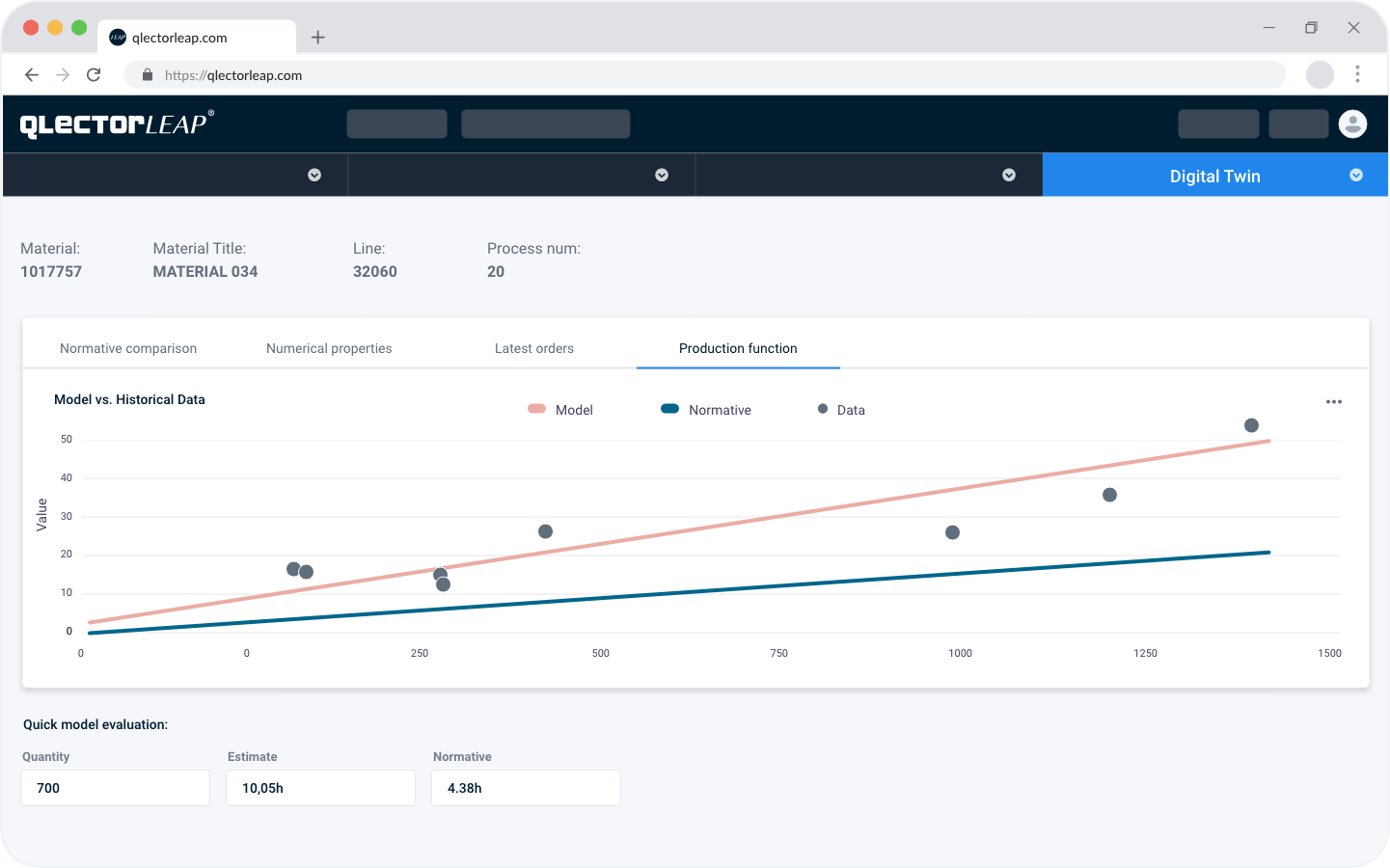

Create an optimal production plan by building a Digital Twin of the production process and material flow, based on data from your MES and ERP systems.

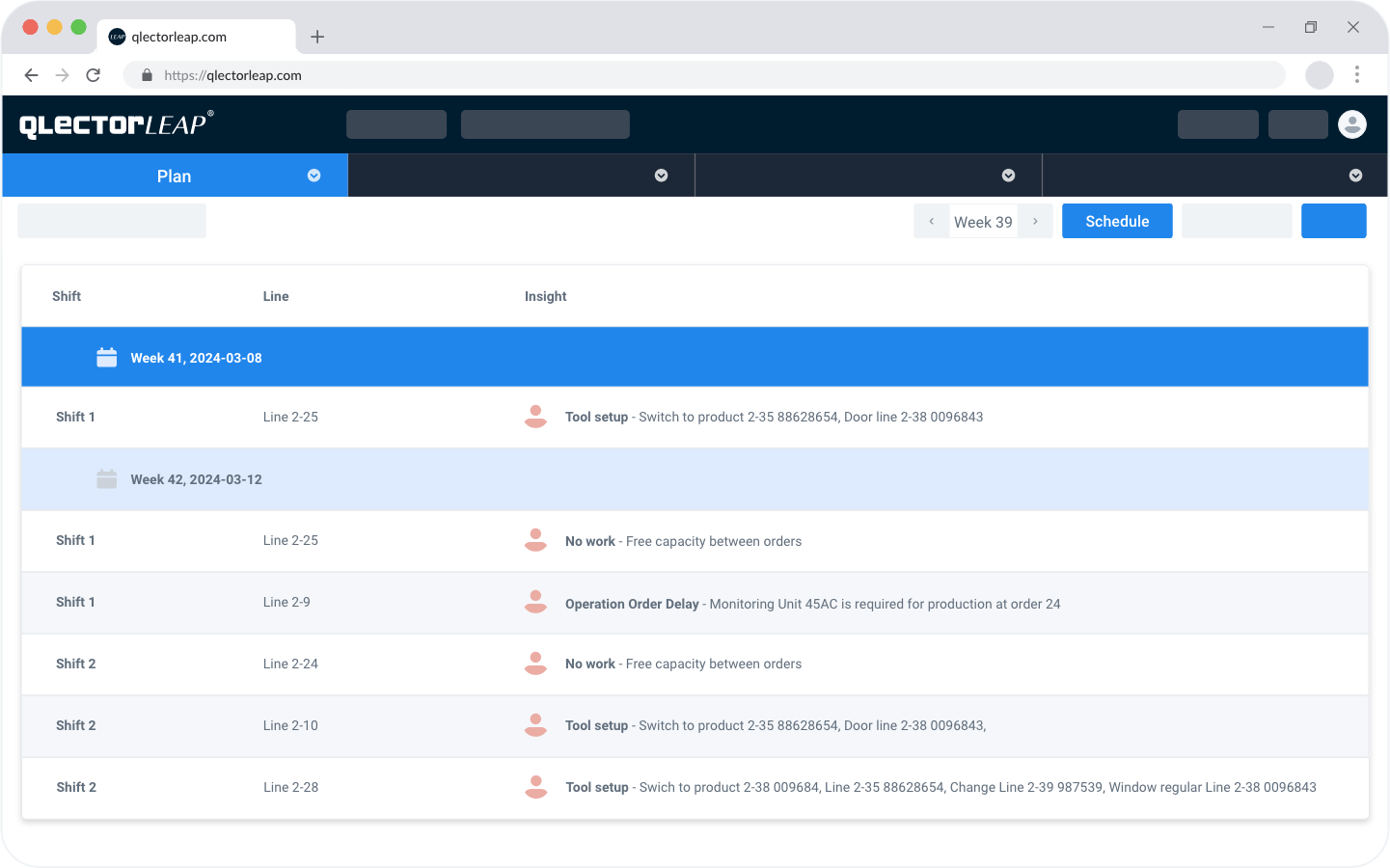

Know What Will Happen

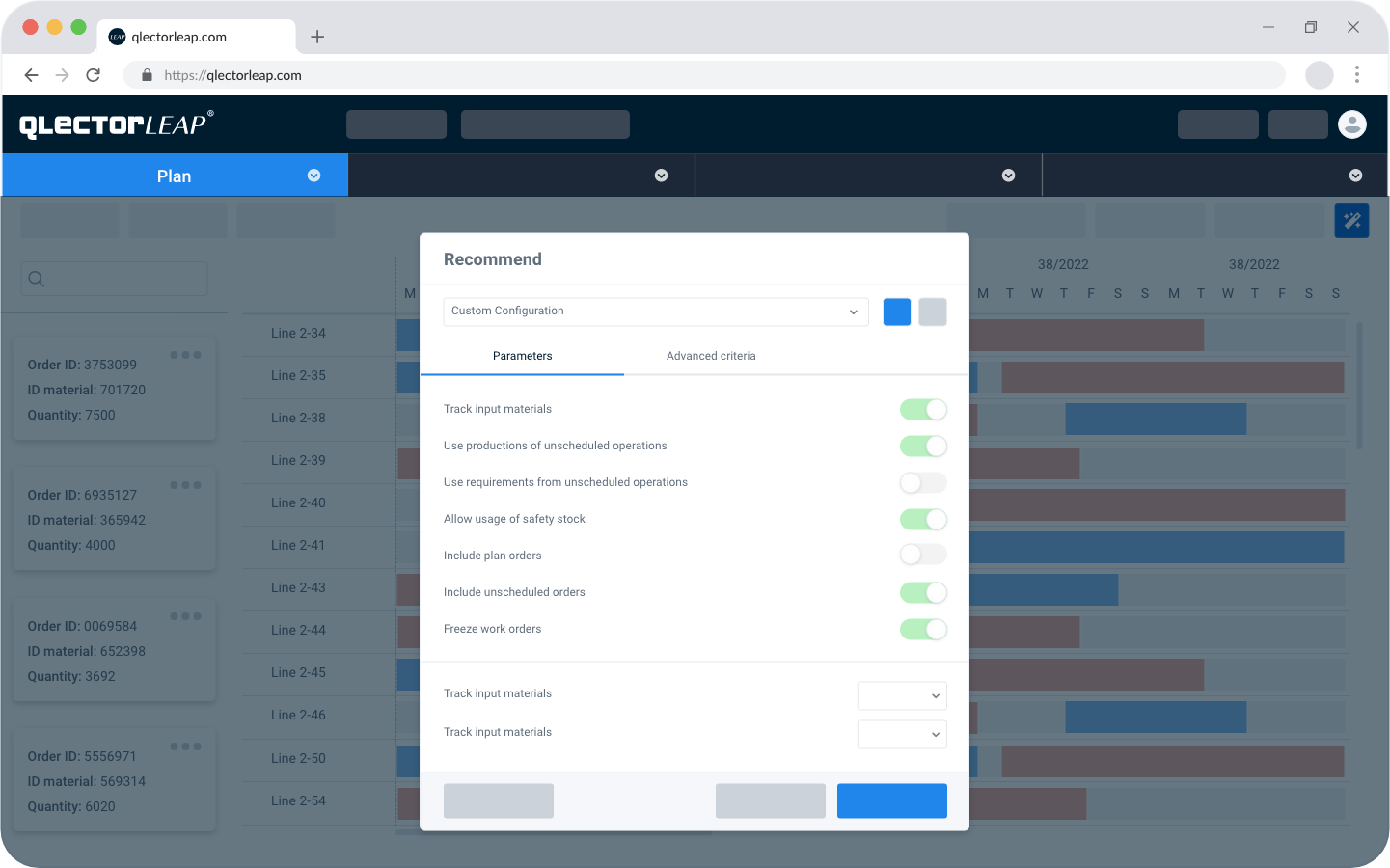

AI helps you predict how much time you need to produce all products, to identify potential problems, and to suggest alternative routings if unplanned events occur.

Sync ERP & MES, Improve Master Data

We combine ERP and production data to help you compare planned norms with actual performance, spot anomalies, and continuously improve your master data.

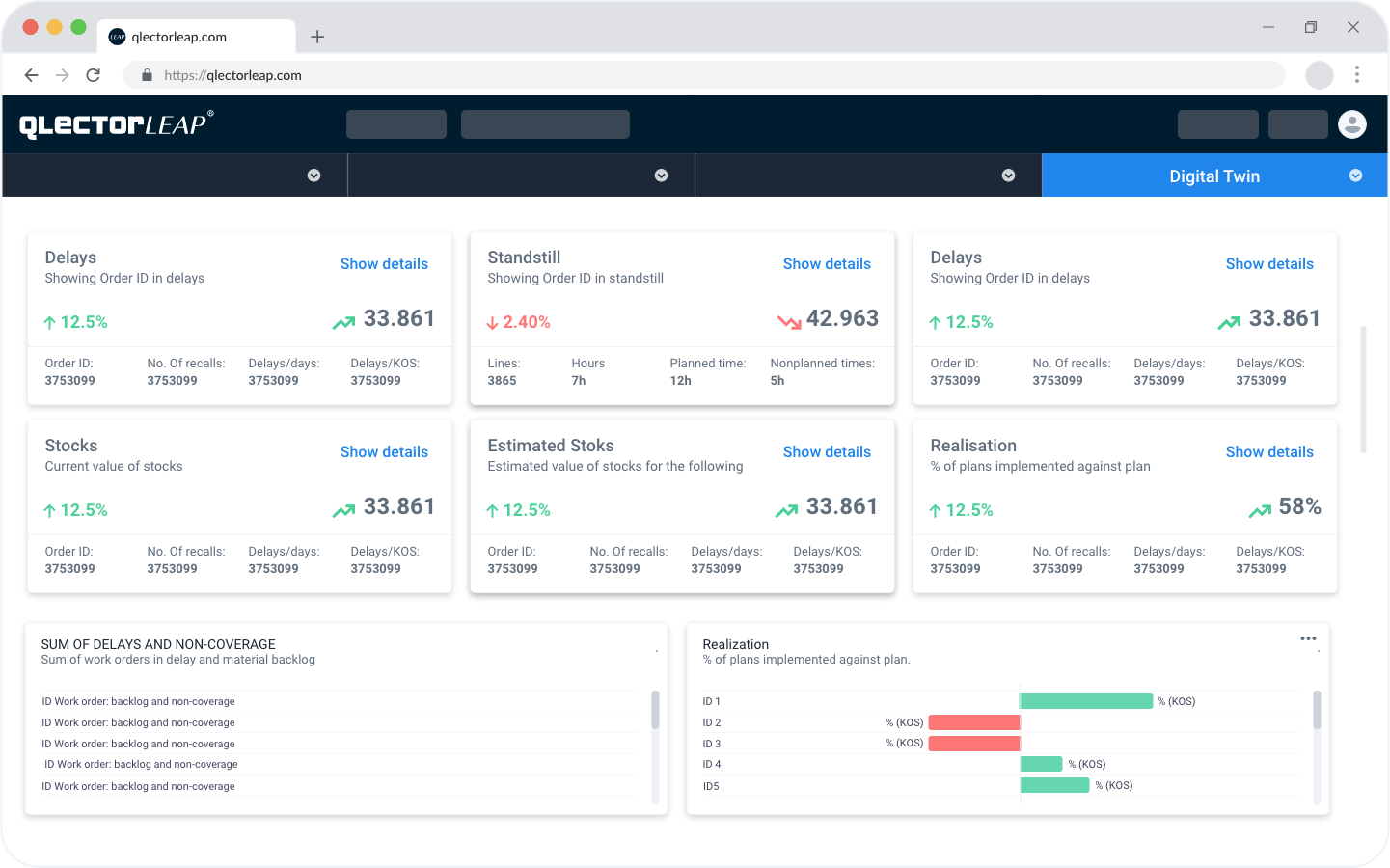

Unified Dashboard

One dashboard connects different departments and provides clear insights into planning, material flow, workforce scheduling, and more.

Anomaly detection

Detect anomalies in production line setups, realization, stock, and gain insights powered by predictions.

Workforce scheduling

Build a data-driven digital twin of each worker based on their skills, limitations (including regulations), real shop-floor performance, and availability, ensuring the right people are in the right roles, and work schedules are optimized for maximum efficiency.

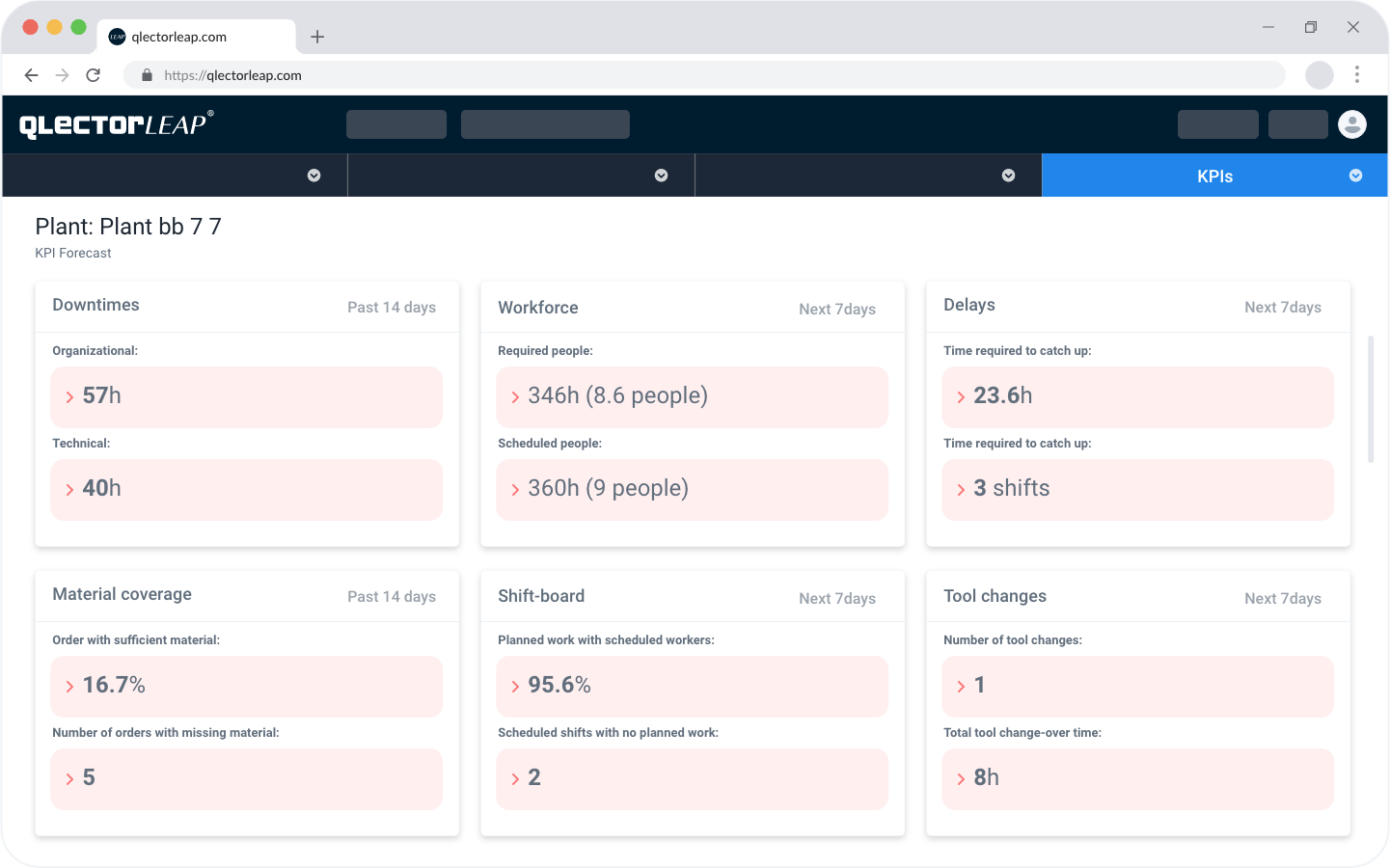

KPIs Calculation & Forecast

Calculate and compare KPIs for different planning scenarios, including future forecasts.

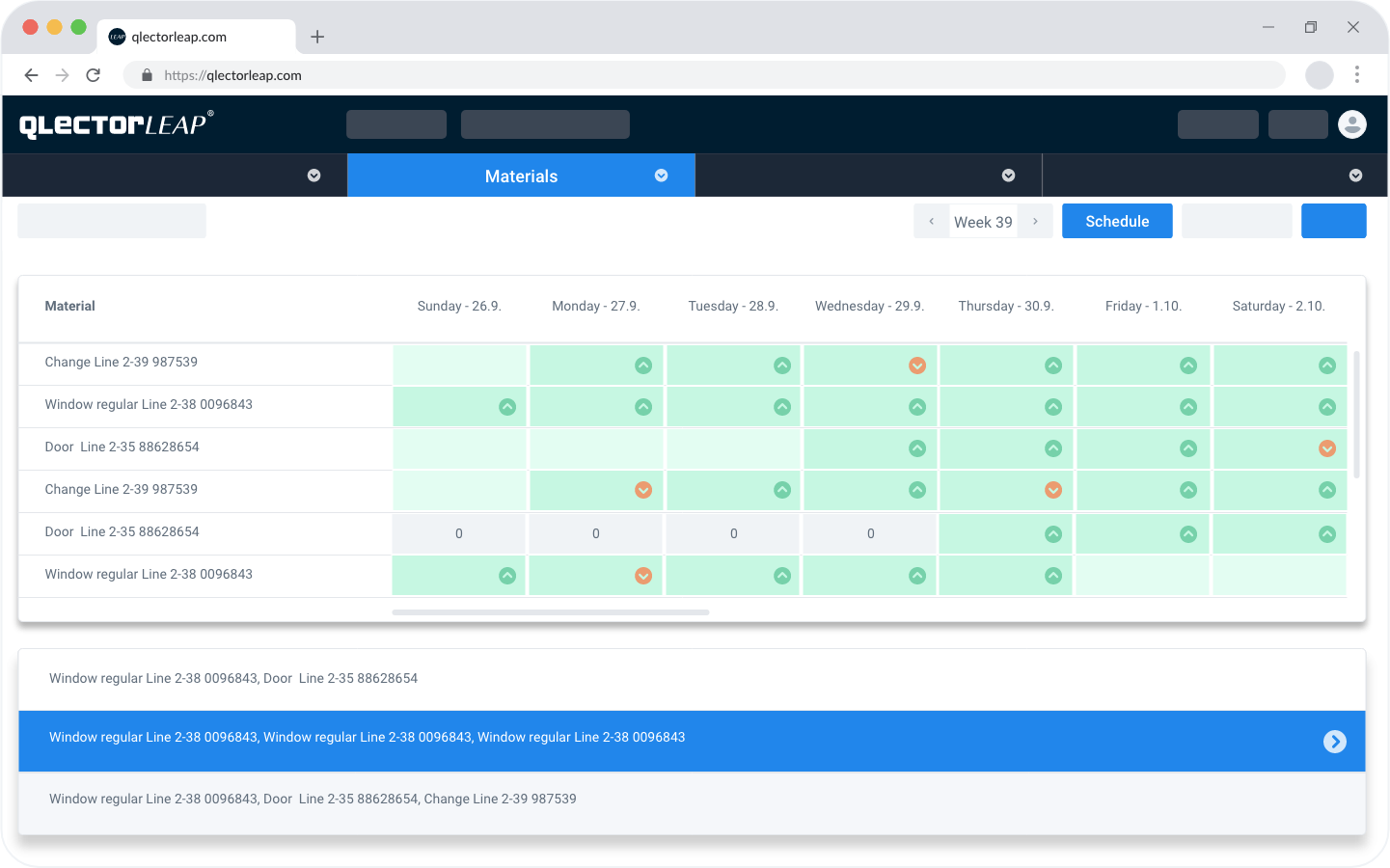

Forecasts of inventory status

The forecast of inventory status assists planners and logisticians in reviewing and early detection of material shortages and optimizing inventory.

Decision making

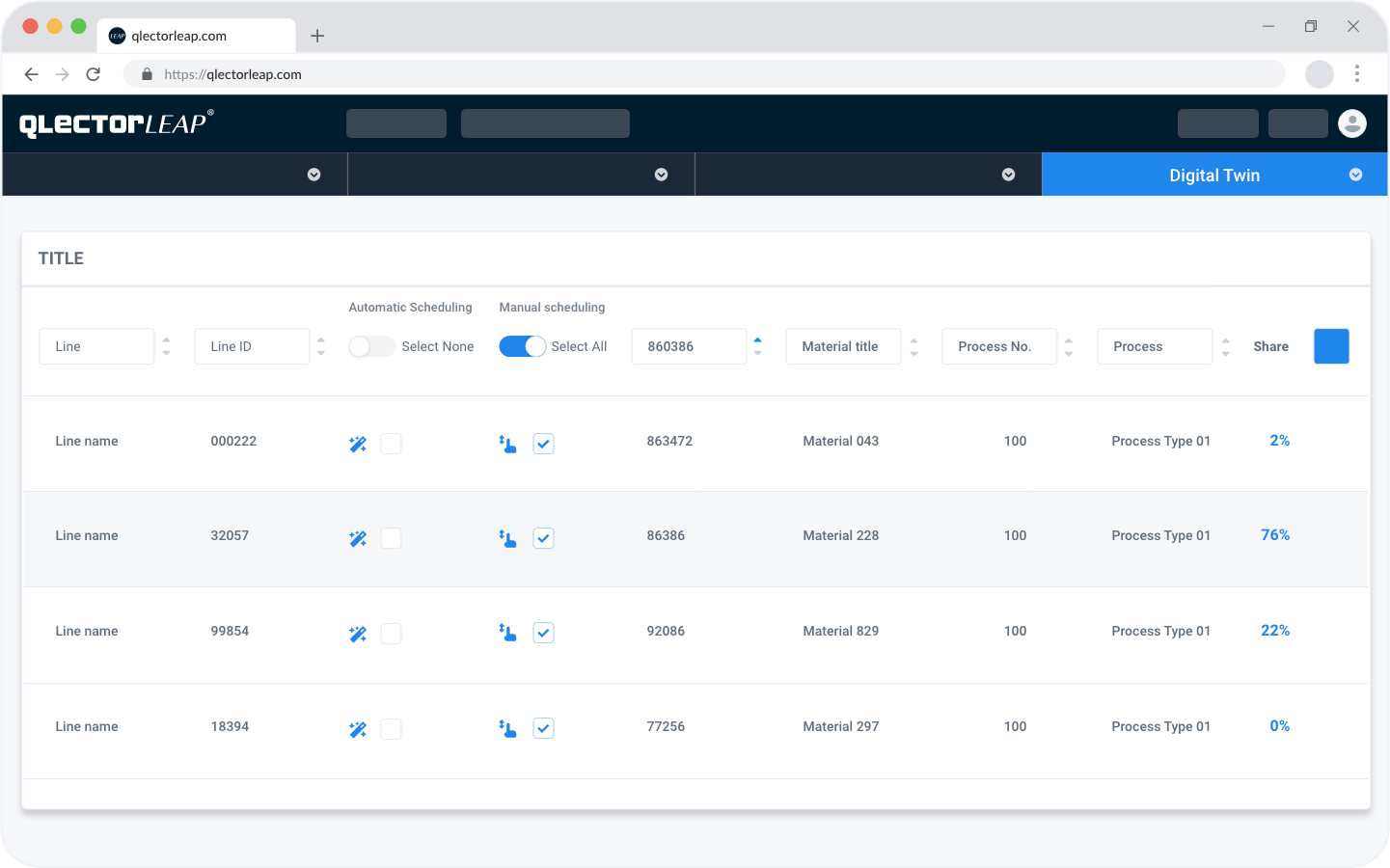

Automated sequencing integrates production and supply chain optimization to generate realistic scenarios for production processes. This functionality is based on advanced AI models that continuously evolve with the arrival of new data.

Automatic Optimization

Automated sequencing integrates production and supply chain optimization to generate realistic scenarios.

Adaptability

Providing predictions, simulations, insights, and alerts for unexpected events, enabling intelligent decision-making with minimal human intervention and proactive actions taken before unplanned events occur.

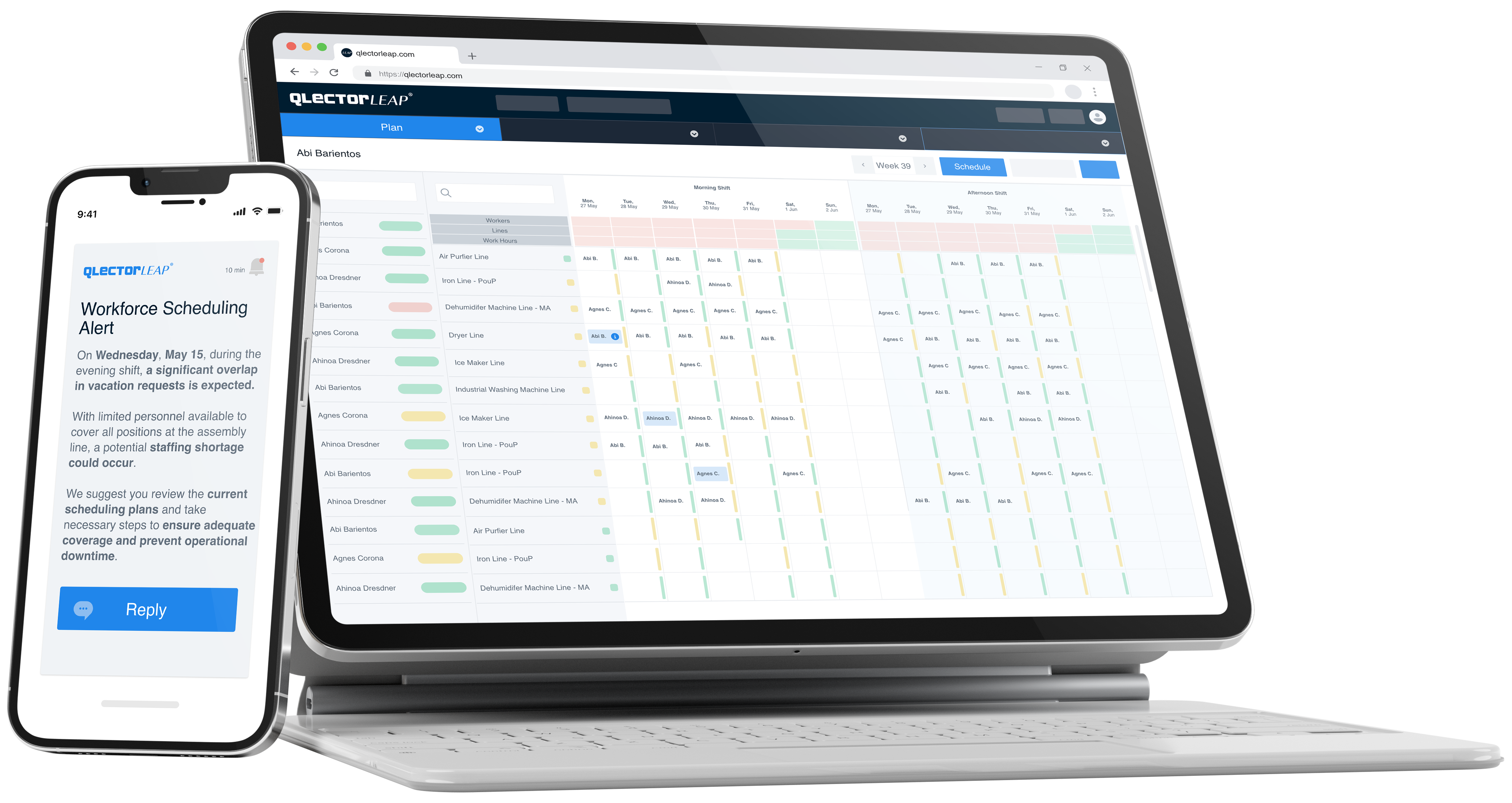

Intelligent Workforce Scheduling Solution

Optimize workforce schedules with AI that aligns people with production plans, real-time demands, and their availability, skills, certifications, and limitations, ensuring the right person is always in the right place at the right time.

Automatic Scheduling

Automates people, shift, and task scheduling, fully integrated with existing IT, ERP, and HR systems. This solution simplifies complex scheduling and reduces manual work.

Right People in the Right Roles

Align people with production plans based on their real-time availability, skills, certifications, and regulations. Ensure every shift has the right person in the right place.

Adapts to the Unexpected

Even with last-minute changes or absences, it keeps workflows running smoothly by using a digital twin of each worker to suggest the best schedules.

Minimal Disruption to Your Operations

Maintain continuity even in dynamic environments. Ensure stable operations by optimizing schedules without constant coordination or manual updates.

Simplify Planning. Empower Teams.

Eliminate spreadsheets, endless calls, and reactive planning. With AI-powered features, your team can focus on what matters: performance, quality, and productivity.

Compliant & Secure

Our solution is GDPR/DSGVO compliant and ISO 27001 certified, ensuring robust data protection, secure operations, and reliable information security.

Real stories,

superior productivity

This is how our customers excel in manufacturing with Qlector's solutions, making everyone's life on the shop floor easier.